Heat Treat Controls & Monitors

Controlling & Monitoring Your Heat Treat Equipment

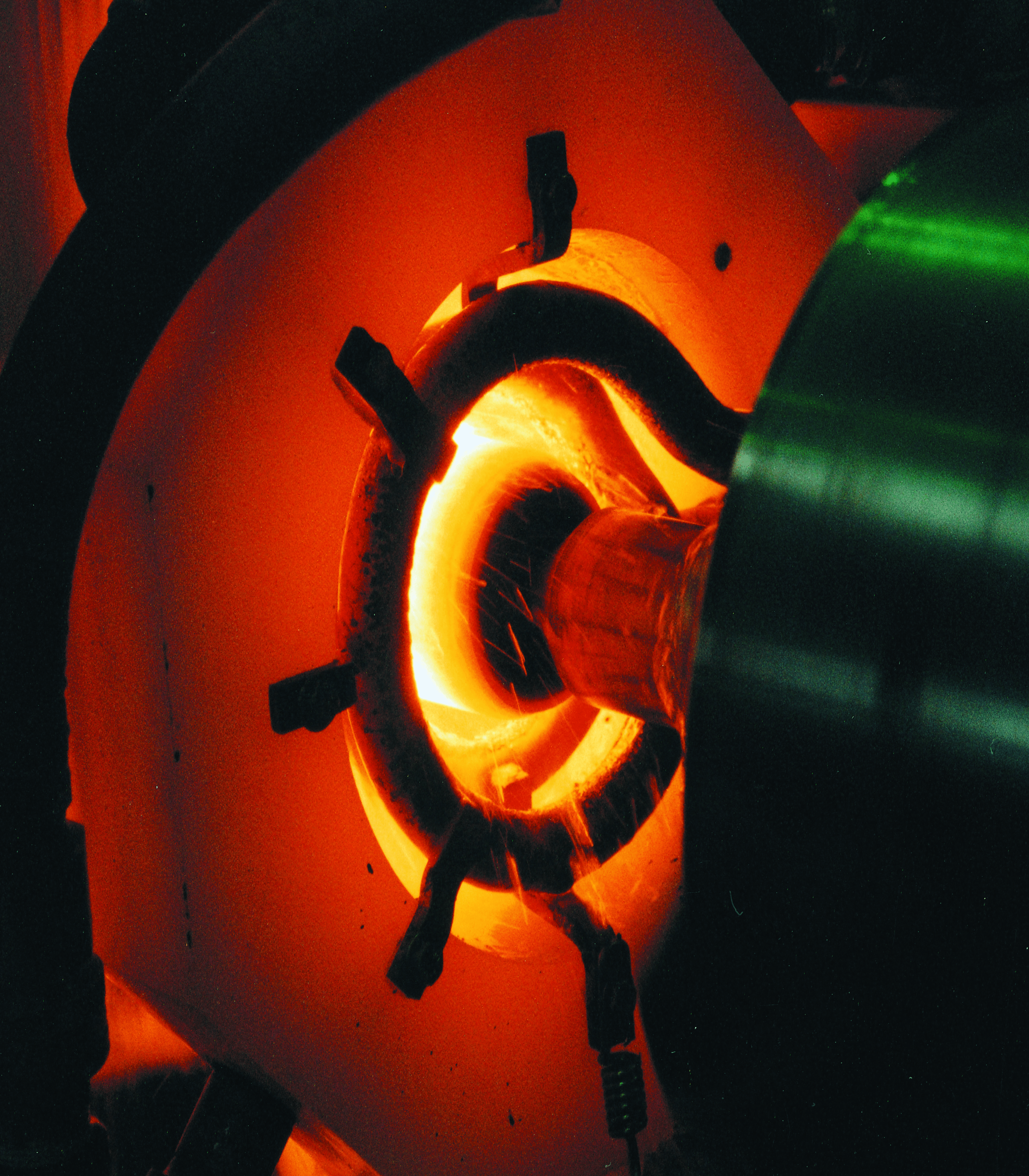

Heat treat systems are known for accuracy and repeatability, but the importance of controlling and monitoring the system parameters and diagnostics plays a significant role in continuously producing quality parts. Ajax TOCCO Magnethermic offers standard and custom heat treating system controls and diagnostics for every new system, as well as retrofit and stand-alone packages for existing systems.

Process Controls and Monitors Include:

- Power Supply Functions

- Energy Levels

- Cycle Times

- Rotation Speed

- Part Recipes

- System Diagnostics

- Scan Position & Speed

- Quench Temperatures

- Part Drawing & Manual Storage

- Warning Alarms

- Maintenance Reminders

- More….

Providing Heat Treating Solutions Since 1916

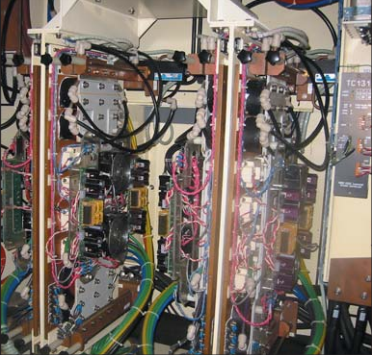

Magnescan TQMS Controls

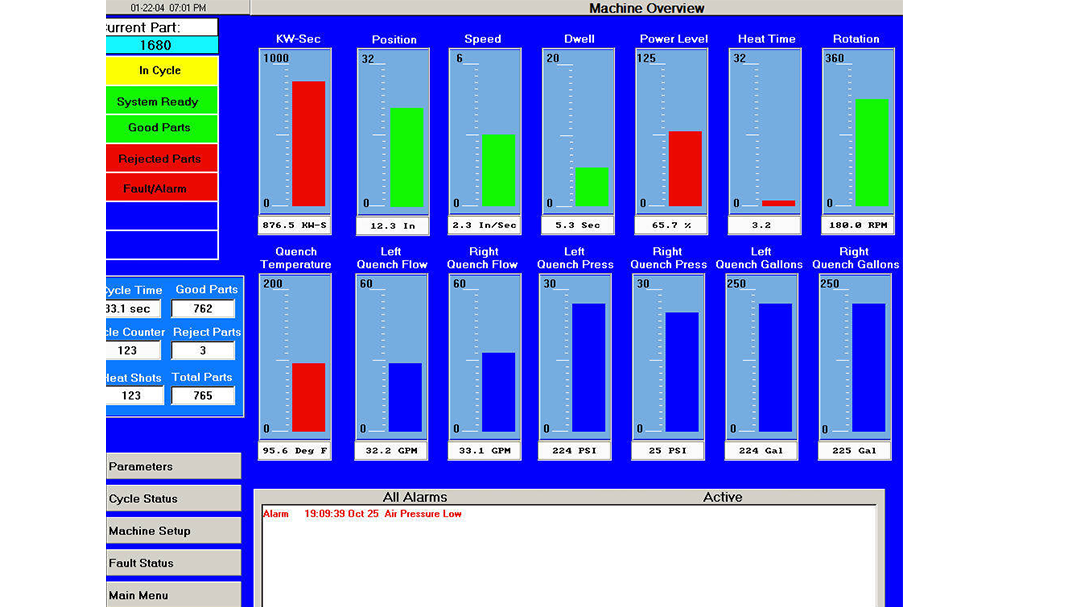

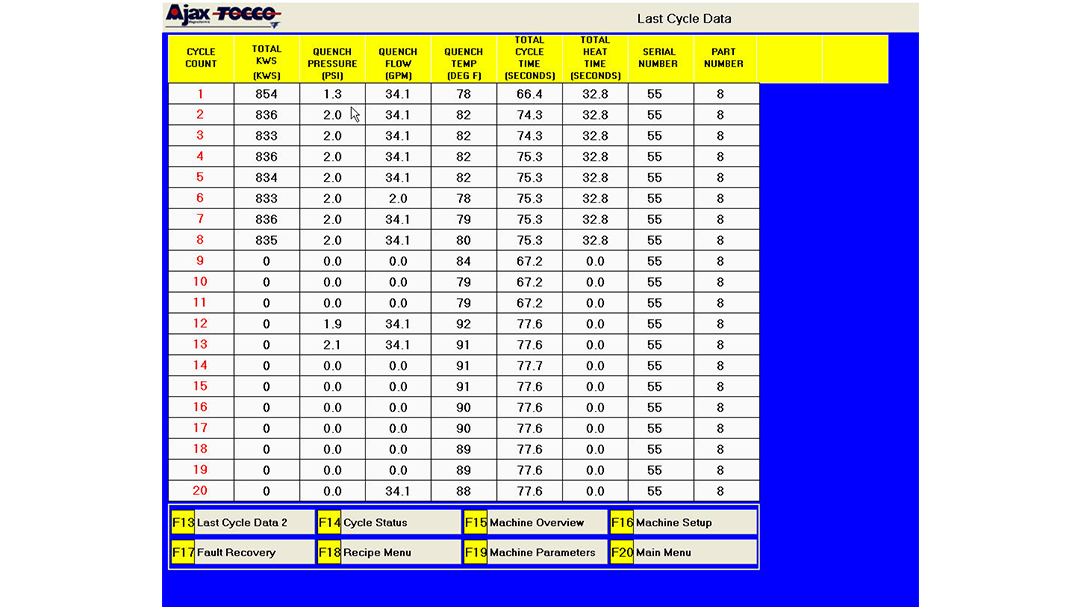

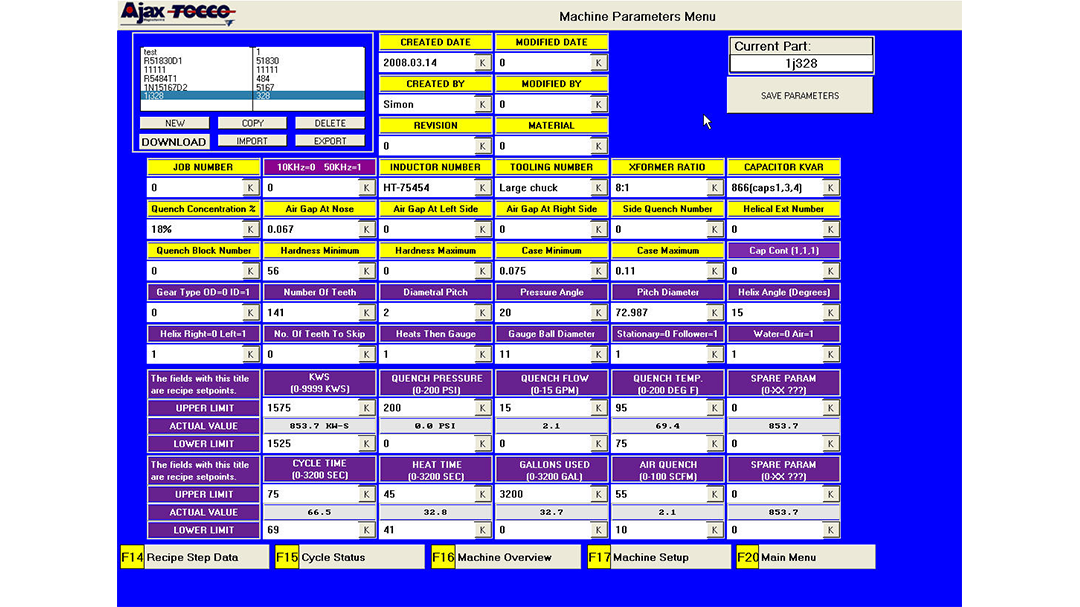

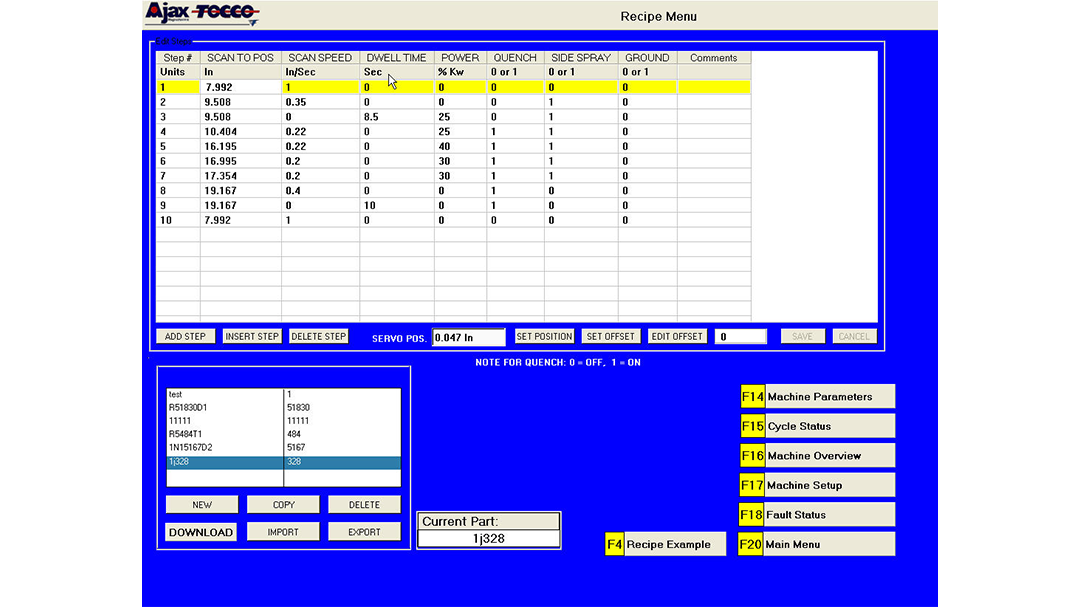

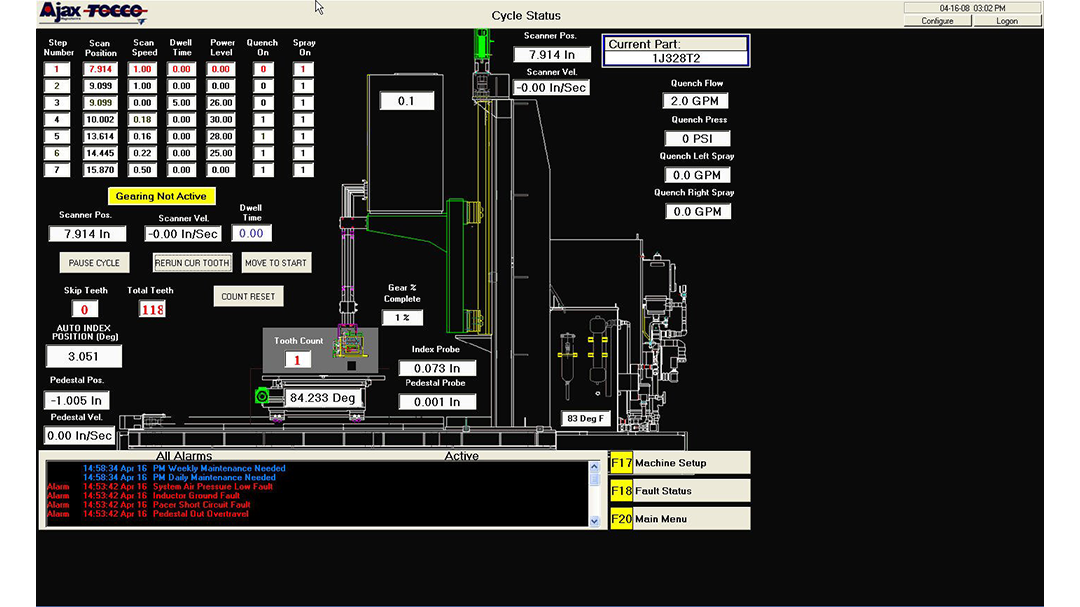

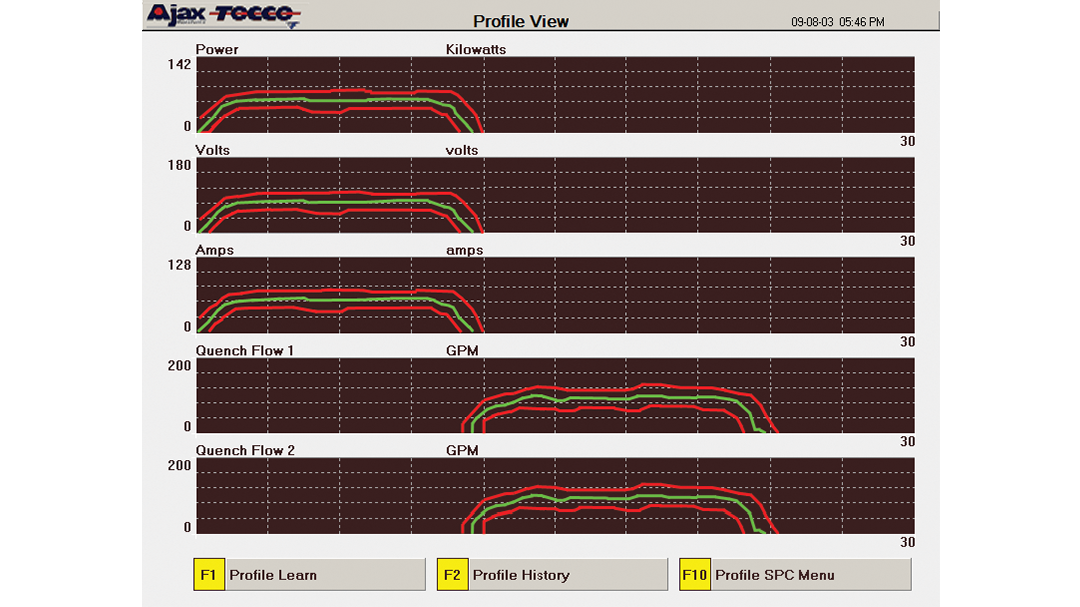

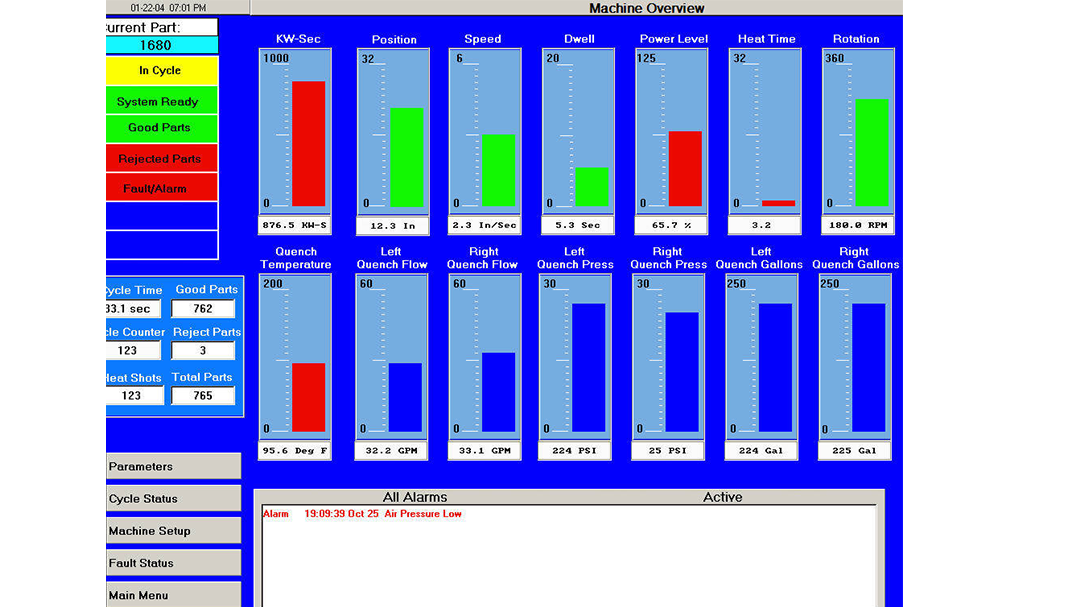

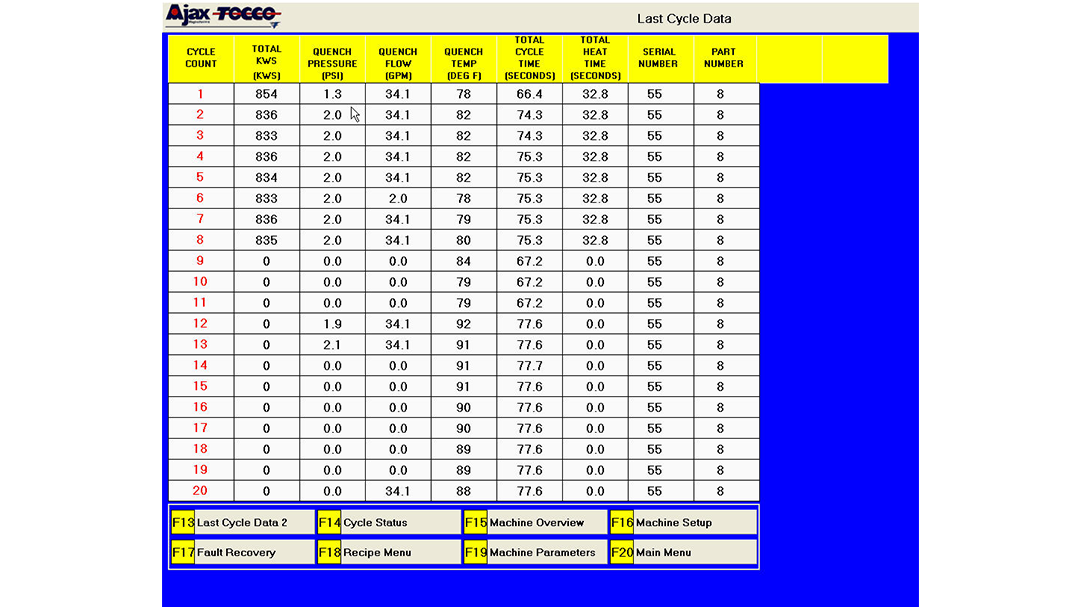

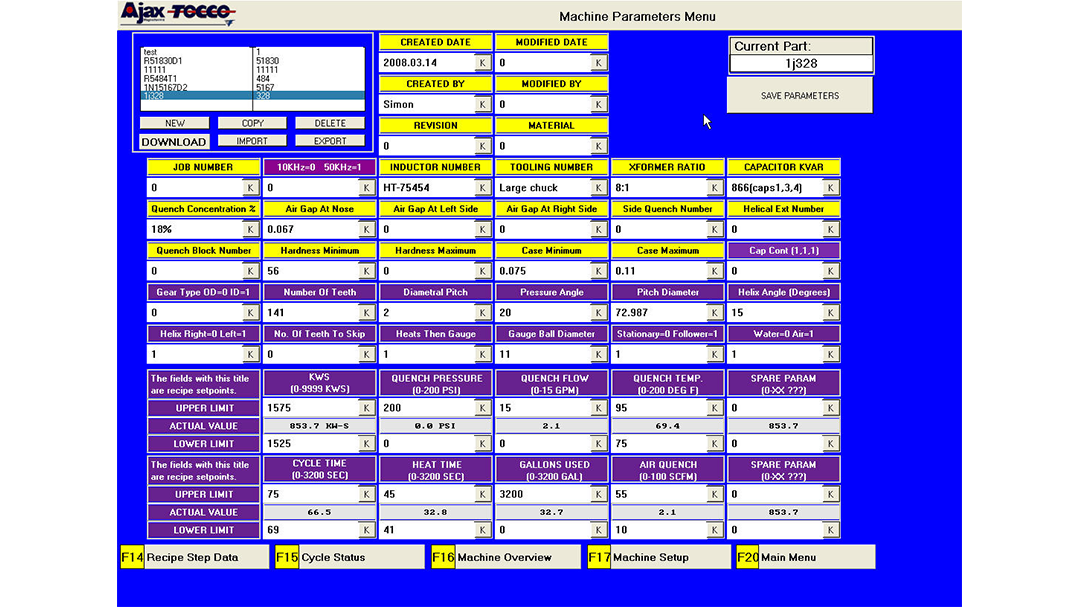

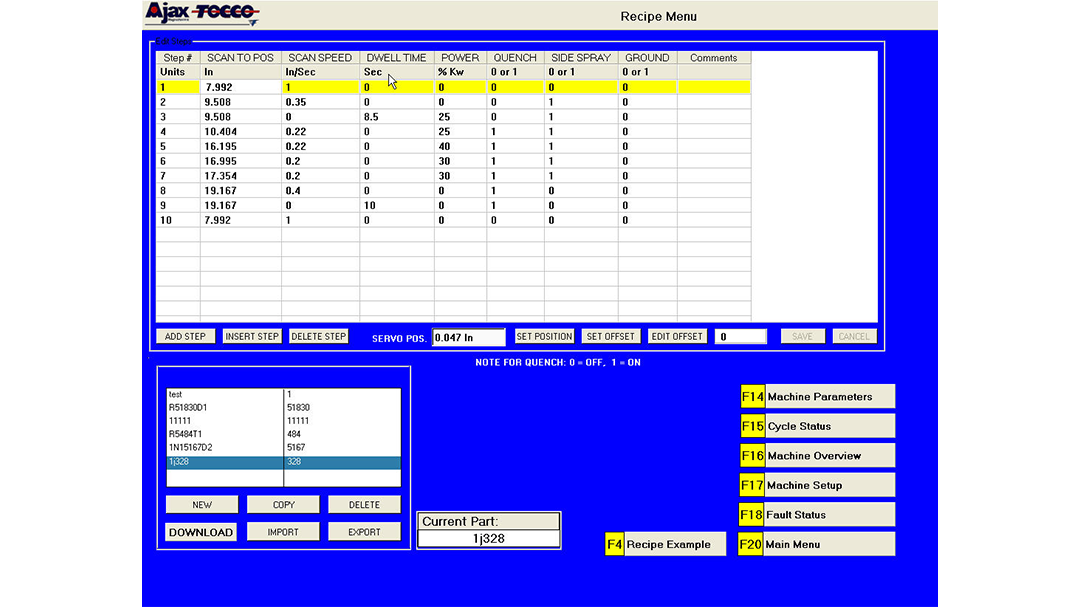

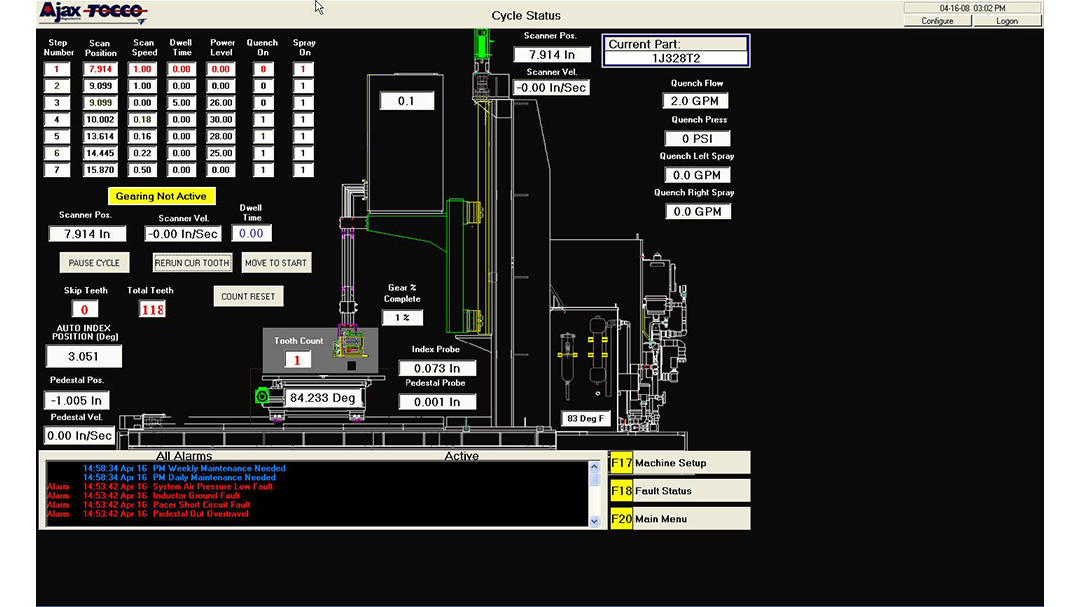

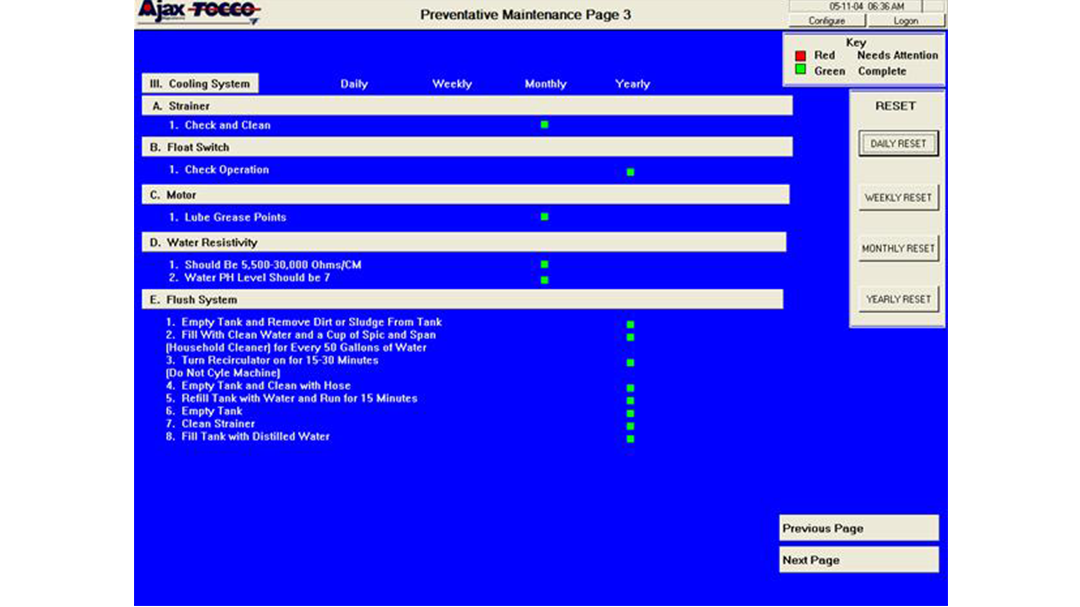

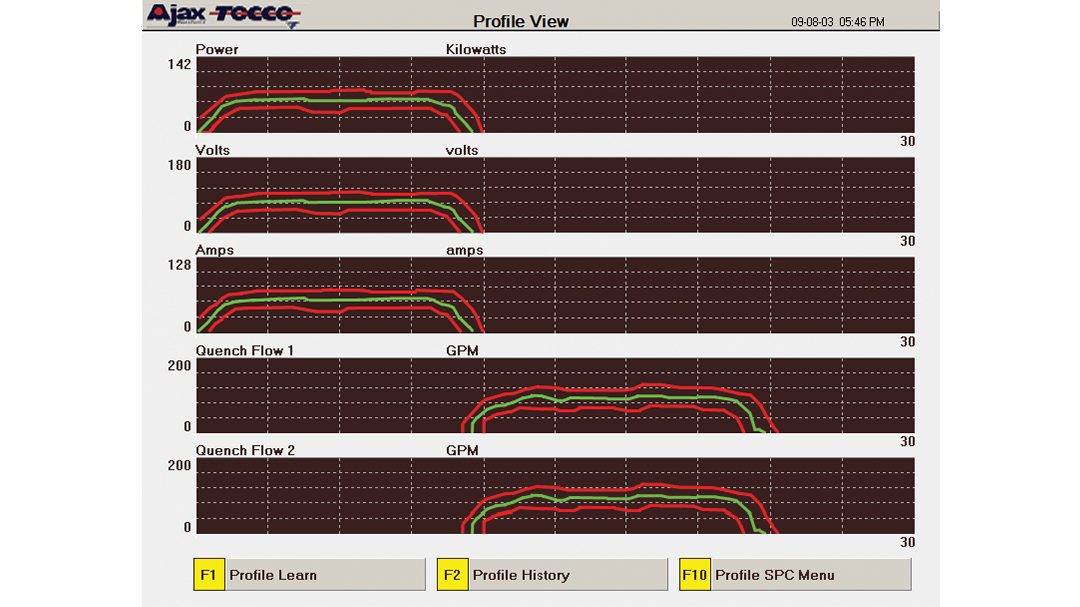

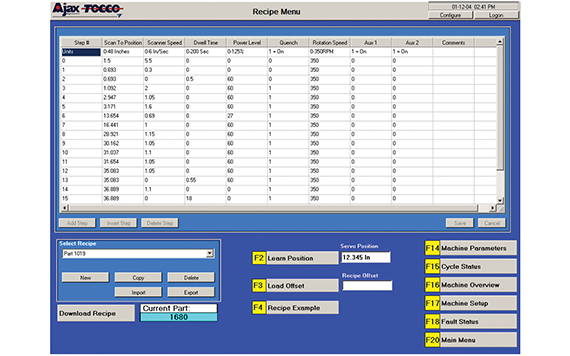

Magnescan TQMS (Total Quality Monitoring System) is Ajax TOCCO's premier control for heat treating applications. Magnescan provides a touch screen HMI with PC interfaced to a PLC and Servo for controlling all operating parameters on the system. Power supply functions, energy levels, scan speeds and position, quench temperatures, cycle times, rotation speed, etc., are all controlled with this system.

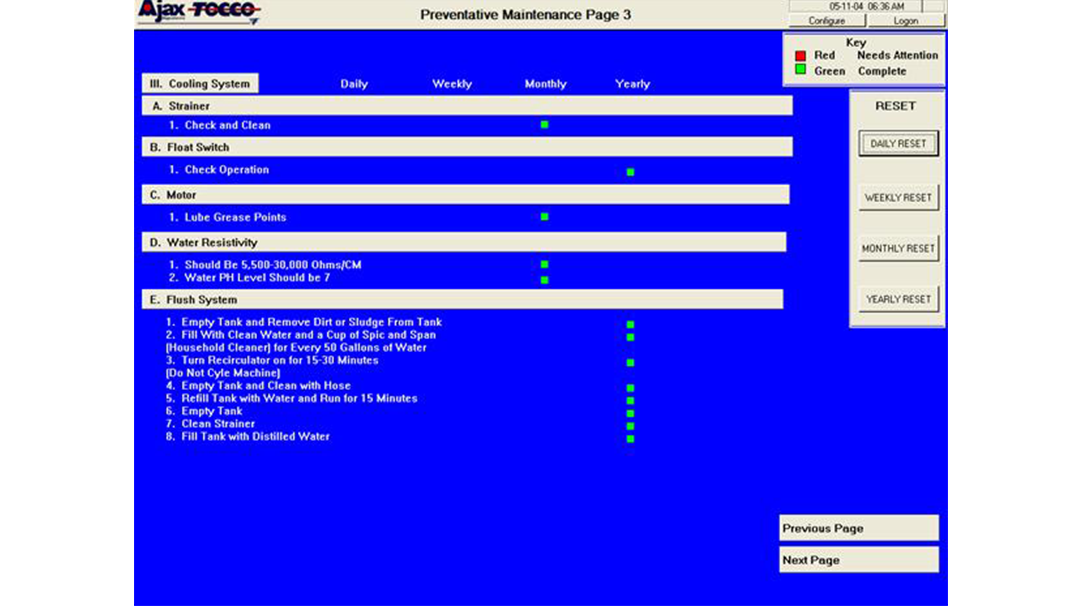

The system monitors all of these functions, stores all critical parameters for each part, and provides SPC data manipulation and graphing capabilities. Part recipes are stored in the PC and storage is only limited by hard drive capacity. All hardware and process alarms are displayed and stored for future reference. System diagnostics, as well as equipment drawings and manuals, are stored for maintenance or operator use. Multiple screens display equipment status, process status, part recipes, SPC functions, and much more.

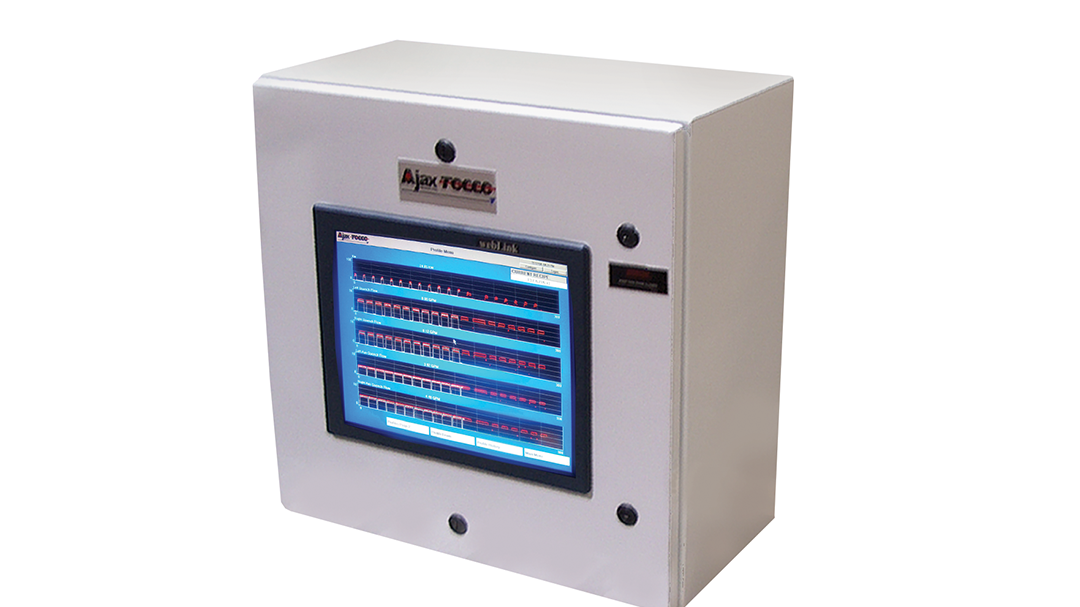

Stand-Alone Process Monitor

The Process Monitor is a stand-alone package available for equipment retrofit that provides all the monitoring features of the Magnescan TQMS package without the control. Existing equipment controls are retained for equipment functionality, but the functions, including energy levels, can be monitored, stored, and manipulated for SPC by our Process Monitor, just as in the TQMS control package.

Custom Heat Treat Controls

Ajax TOCCO maintains an expert staff of controls engineers with the capability to design custom control packages for any type of process control. Any control package from the very basic to the most sophisticated can be developed for your application.

Heat Treat Resources

Resources related to Heat Treating Technology.

Development Of A State-of-the-Art Crankshaft Hardening System

Aug 03, 2007 by Ajax TOCCO MagnethermicLearn how Ajax TOCCO Magnethermic developed an improved automotive crankshaft hardening system that meets market requirements.

Induction Tooling – Advancements In Induction Heating Tooling Technology

Aug 03, 2007 by Ajax TOCCO MagnethermicThe induction heating tooling industry has made progress, but there still is a long way to go to advance the technology. Learn more.

Equipment & Hardware Materials Technology

Apr 02, 2007 by Ajax TOCCO MagnethermicThe charter of the ASM Heat Treating Society’s R&D Committee is to identify future technological needs of the heat treating industry. Learn more.

Things To Remember About Induction Heat Treating

Apr 02, 2007 by Ajax TOCCO MagnethermicLearn about the factors that make induction heat treating a process of choice for many engineers as well as some basic tips to be mindful of.

Ajax TOCCO Magnethermic Awarded Order for Induction Scanner to Harden Transmission Components

Apr 11, 2013 by Ajax TOCCO MagnethermicAjax TOCCO has been awarded an order for an industrial-duty, dual-spindle servo-controlled vertical scanner to induction harden inner rings used in transmissions. Learn more.

Thank you for requesting access to this brochure.

You can access your download by clicking here.