Material Handling for Forging

Flexible Forging Material Handling Solutions

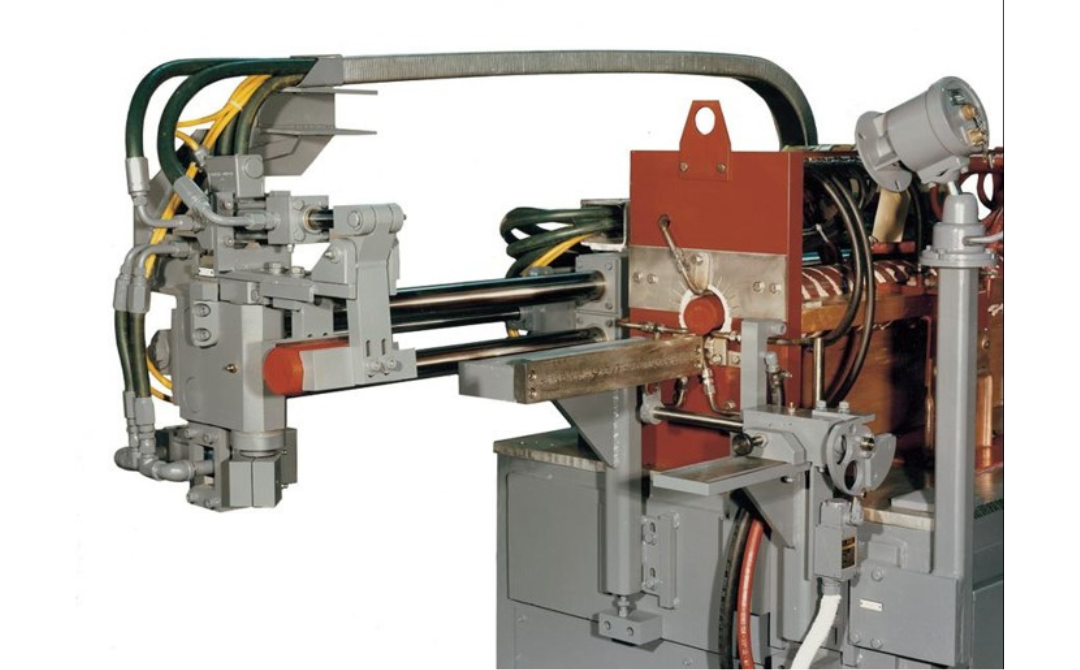

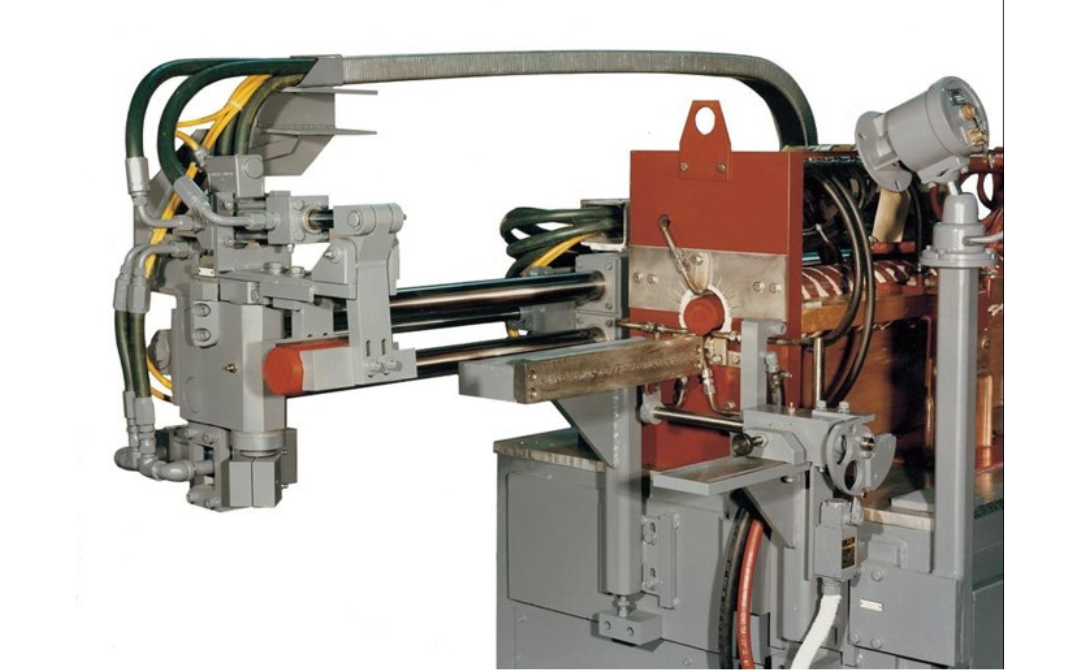

Experience and know-how play an important role in recommending the right equipment to handle your heating requirements dependably and economically. Properly designed induction heating equipment offers many advantages. The difference in equipment is in its reliability and the way it is applied to solve a heating problem. Each component has a function to perform. The components selected are developed by Ajax TOCCO Magnethermic specifically for induction heating applications. As a result, we offer a full range of power sources, frequencies, inductor designs, and handling components to ensure that each installation is designed for your specific application.

.jpg?width=1080&height=676&name=Forging-Material-Handling-Fast-Extractor_1080x607px%20(1).jpg)

.jpg)

Efficient and Streamlined for Maximum Productivity

Ajax TOCCO’s power supplies have been streamlined to occupy 50% less floor space than competitive units. Ajax TOCCO has also solved the age-old problem of how to heat a wide range of workpieces at the highest electrical efficiency with a minimal number of coil sets. Transmission losses have been minimized by shortening lead lengths, butting coils end

to end, and making use of integral power systems.

.jpg?width=570&height=356&name=Forging-PowerZone-2-Coil-Compact_570x356px%20(1).jpg)

Versatile Equipment and Research Capabilities

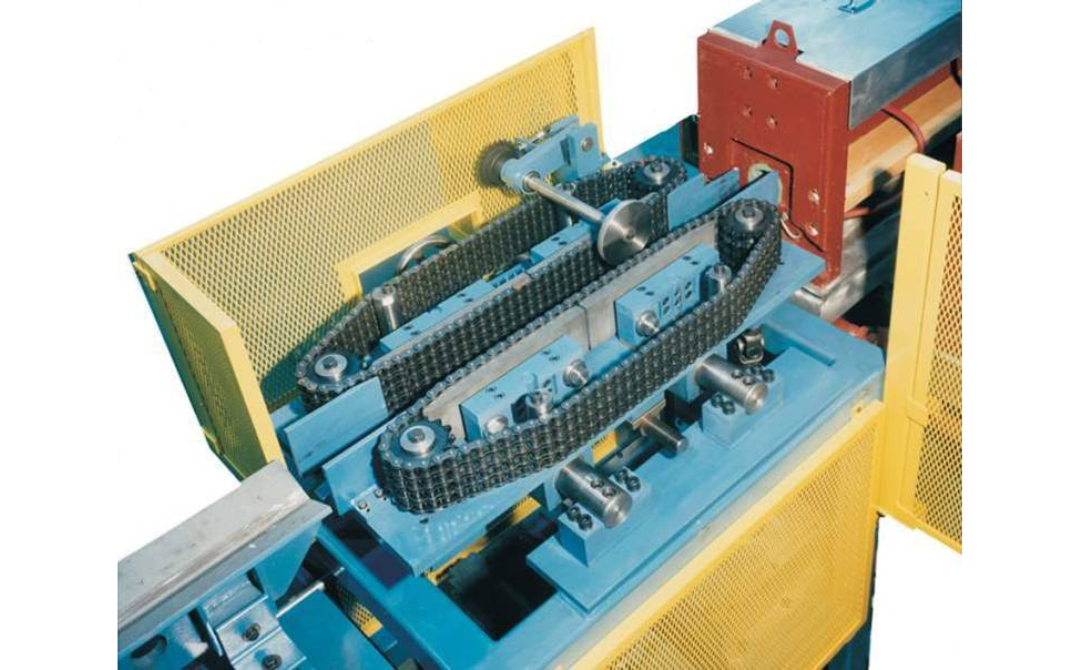

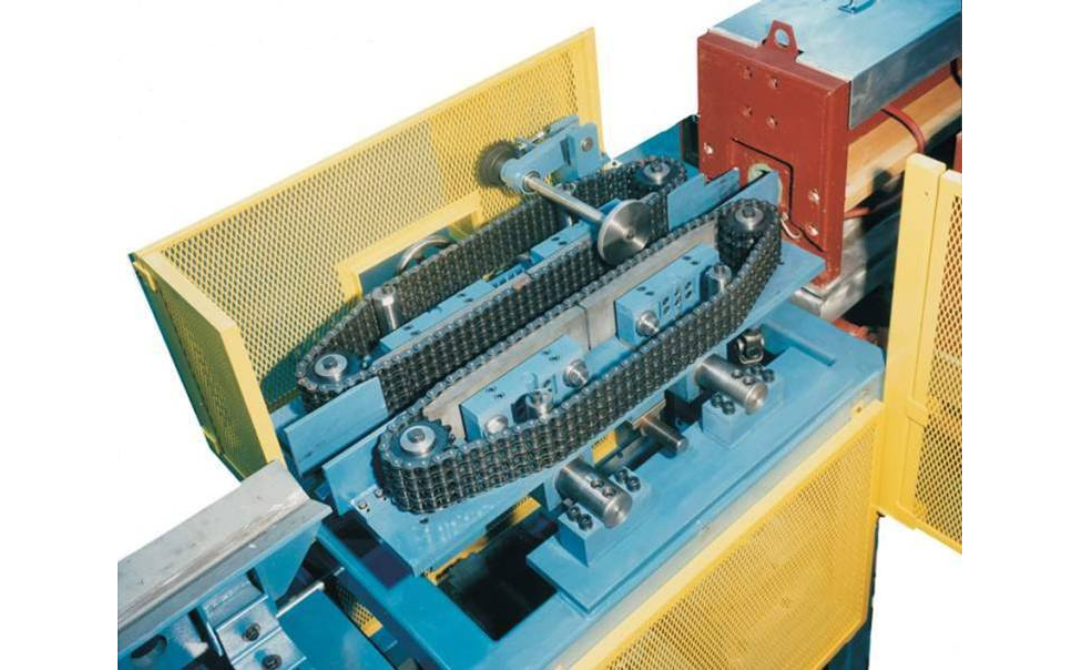

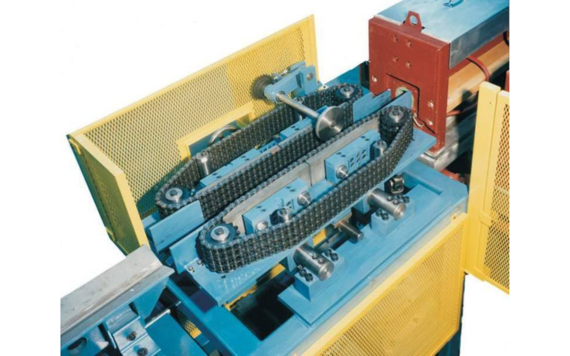

Whether your forging system demands an incremental feed, a continuous feed, or a propulsion system that keeps billets separated, Ajax TOCCO has modern, proven units in the field plus the technology to select and furnish the best equipment for the forger’s needs. A full-time research and development department is also available for test heats or laboratory work.

Thank you for requesting access to this brochure.

You can access your download by clicking here.