Exploring Ajax TOCCO Magnethermic:

We Have the Facts

Dive into the realm of Ajax TOCCO, the industry's trusted expert in induction heating technology. Our comprehensive FAQ section is tailored to help you understand our products, services, and technical specifics.

We hold the facts, translating complex tech into simple understanding. With Ajax TOCCO, you're not just exploring—you're mastering the industry with us, your expert guide.

-

What is Induction Heating?

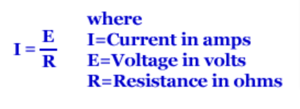

Ohm’s Law

Ohm's Law states that in a simple electrical circuit, the strength of a current (I) flowing through a resistance (R) is proportional to the applied voltage (E). It is expressed by the formula:

Thus, if you increase the voltage, and resistance remains the same, the current will increase proportionately.

Induction Heating

With induction heating, we substitute an induced current for a direct one, which is of course the principle of the transformer. It works this way. Alternating current flowing through the primary coils of the transformer creates an electromagnetic alternating field. Since the reverse is also true, by placing secondary coils within that field, we will induce a current to flow through them. And, depending on the respective number of electrical turns in the primary and the secondary, we can step up or step down the voltage levels. It is the voltage in the secondary turns which, when applied to heating elements, creates the energy to heat or melt metals.Resistive Heating Illustrated

.png?width=250&height=232&name=2-General-Internal-FAQ.docx%20-%20Google%20Docs%20(1).png)

.png?width=375&height=234&name=2-General-Internal-FAQ.docx%20-%20Google%20Docs%20(2).png)

Current flow is induced in the secondary circuit by placing the secondary turns within the changing magnetic field created by the primary turns.

Resistive Heating

Resistance is well named, for it opposes current flow. The lower the resistance, the higher the current flow in the circuit, and hence the greater the power. This power (P) is the rate at which electrical energy is transformed into heat. It is expressed by the formula:.png?width=300&height=121&name=2-General-Internal-FAQ.docx%20-%20Google%20Docs%20(3).png)

This heat can be put to a good purpose and is the principle behind heating elements that you find in hair dryers and baseboard heaters. However, such direct production of heat is inefficient, localized, and difficult to control. For industrial purposes, it is preferable to produce heat by using an induced current rather than a direct one.

-

What are the benefits of Induction Heating?

Quality

Precise control provides consistent temperature uniformity and exact repeatability. Forgings have fewer inclusions and improved surface finish because of reduced scale.

Flexibility

Induction heats only the workpiece using the minimally needed energy to achieve the exact temperature. New solid-state power supplies seek the best frequency for the load, further improving operating flexibility and efficiency.

Productivity

An integral induction heating system increases productivity because it is easily integrated with in-place processes. An induction heater, not the operator, sets the pace for the production rate. Induction heaters can be started from cold to achieve full production rates within minutes. Heaters are designed for automatic hold cycles during delays and rapid recovery at the restart.

Limited Material in Process

Induction heating requires fewer parts in process which reduces the chance of rescheduling errors and substantially reduces material inventories.

Reduced Scale & Increased Tooling Life

Induction heating increases the workpiece temperature in the shortest possible time and in effect, reduces the amount of scale which improves the surface finish of the end product and increases the customer’s tooling life.

Maintenance

The only use of refractory in an induction system is in the coils. With the benefit of long coil life in an ATM induction system, refractory repairs and relining are greatly minimized. Die life is also extended with the drastic scale reduction.

Yield

Typical scale loss in gas-fired furnaces is 3% and from induction is 0.5%. Consequently, for each ton of forgings, the raw steel purchased is reduced by 2.5%.

Work Environment

Since there is no heat, or products of combustion, a cleaner and a more comfortable environment will enhance the workplace.

-

What are heat treating fundamentals?

Isothermal Transformation Diagram

.png?width=566&height=364&name=2-General-Internal-FAQ.docx%20-%20Google%20Docs%20(4).png)

Hardness & Hardening Temperature vs Carbon

.png?width=556&height=352&name=2-General-Internal-FAQ.docx%20-%20Google%20Docs%20(5).png)

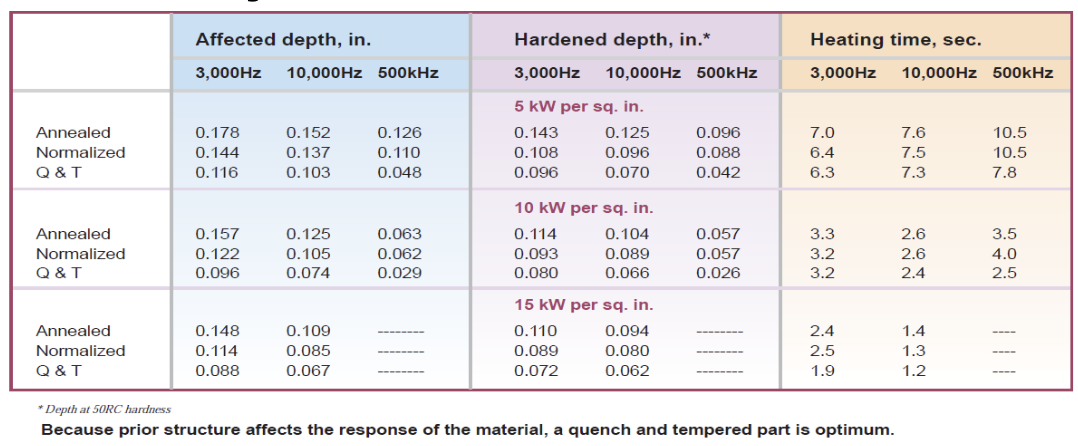

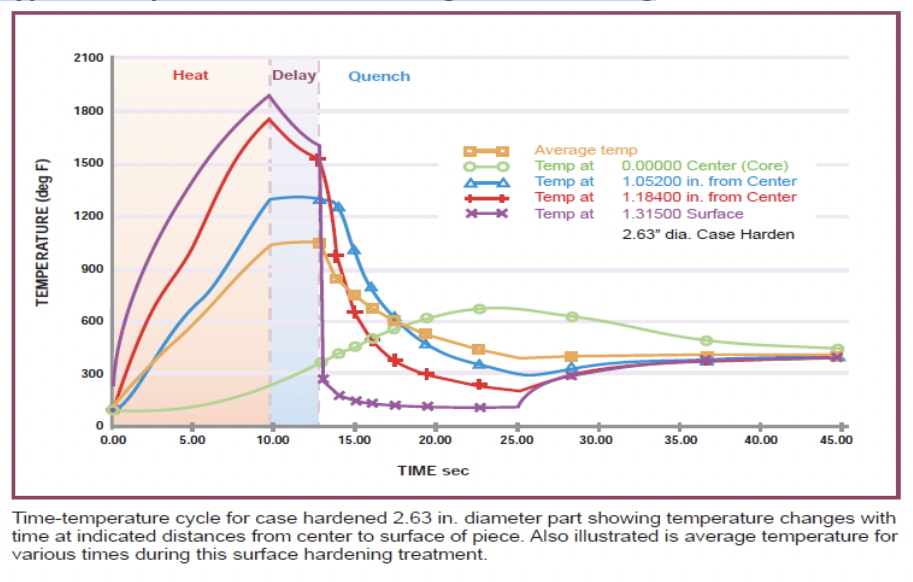

Induction Hardening 1045 Steel

Typical Temperature Profiles through Heat Treating

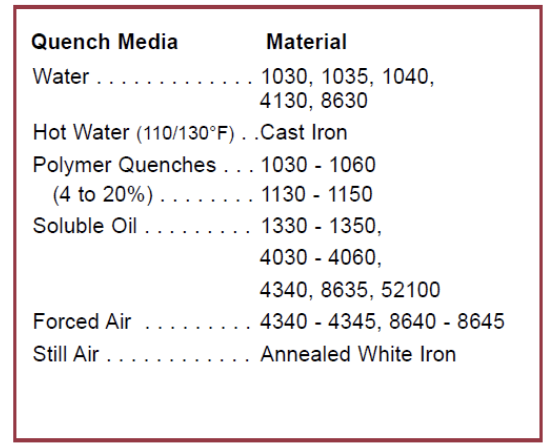

Quench Media for Hardening

-

What can I do to ensure maximum uptime?

At Ajax TOCCO, we understand the importance of consistent productivity. Unplanned delays and emergency breakdowns not only disrupt your workflow but also result in substantial financial losses. That's why we meticulously design preventative maintenance programs tailored to your unique production schedules.

Our expertly-crafted programs focus on the optimal upkeep of your induction heating equipment, taking into consideration factors such as usage patterns, environmental conditions, and specific operational requirements. We aim to maximize the uptime of your equipment, ensuring that your operations run smoothly and efficiently.

Years of experience and customer feedback have proven the effectiveness of our approach. Our clients consistently report reductions in emergency breakdowns and costly unscheduled delays, allowing for uninterrupted production and improved profitability.

In addition, our maintenance programs offer proactive support, identifying potential issues before they escalate into serious problems. This not only prolongs the lifespan of your equipment but also enhances safety and reliability.

Unlocking Knowledge:

Your Ajax TOCCO Resources Hub

All you need to know about induction heating.

Development Of A State-of-the-Art Crankshaft Hardening System

Aug 03, 2007 by Ajax TOCCO MagnethermicLearn how Ajax TOCCO Magnethermic developed an improved automotive crankshaft hardening system that meets market requirements.

Thank you for requesting access to this brochure.

You can access your download by clicking here.