Heat Treat Scanners

Induction Heat Treating Scanning Equipment

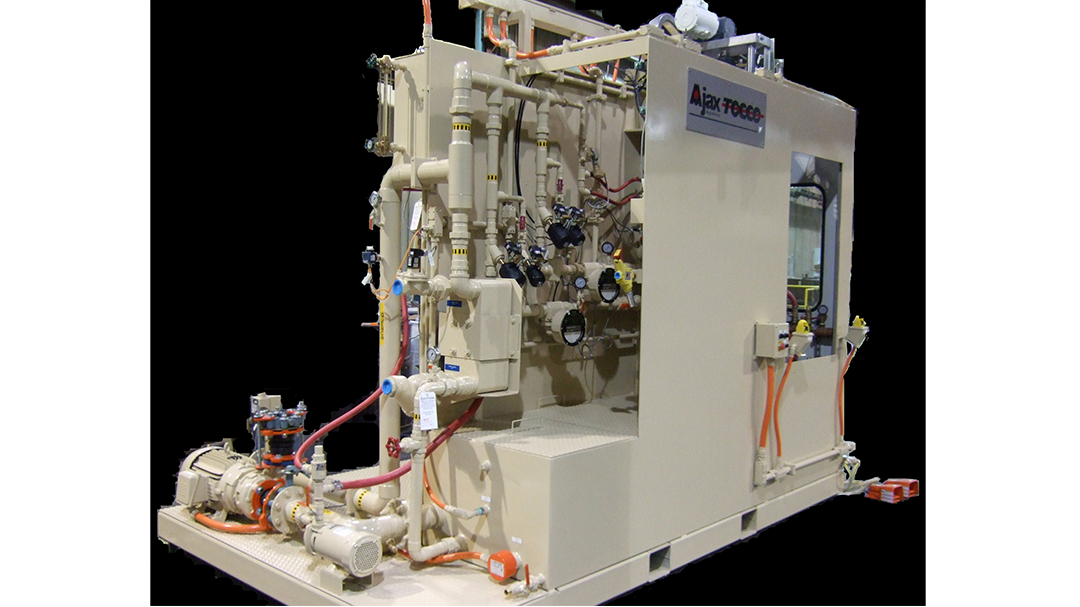

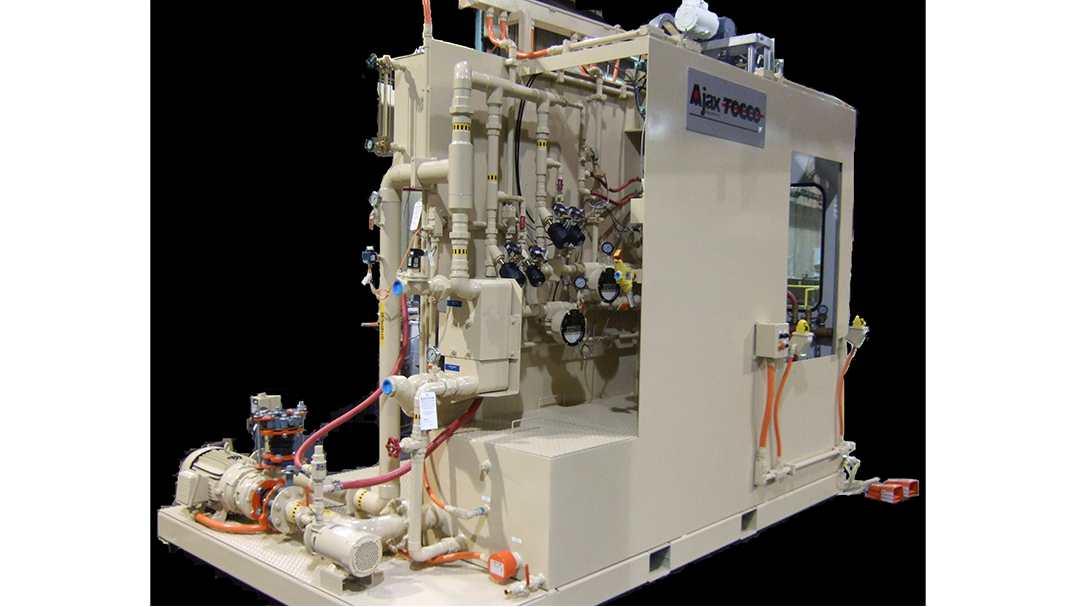

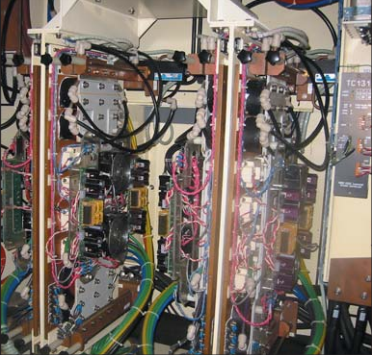

Choosing the right equipment for your heat treating project can be challenging. Factors, such as the size and configuration of the work to be heated, the production rate required, and the type of heating help determine the suggested handling approach. Ajax TOCCO’s experienced engineers analyze your heating applications to provide the most efficient and economical design.

We offer a variety of scanning systems including vertical, horizontal, and tooth-by-tooth to heat treat hundreds of variations and sizes of parts.

Watch Heat Treat Scanners In Action

Providing Solutions since 1916

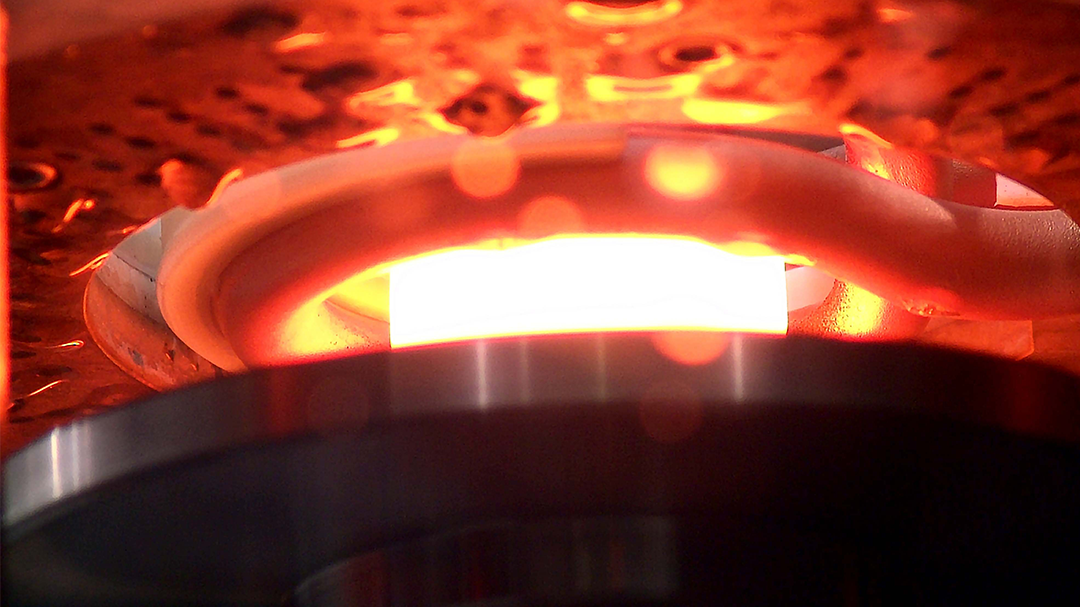

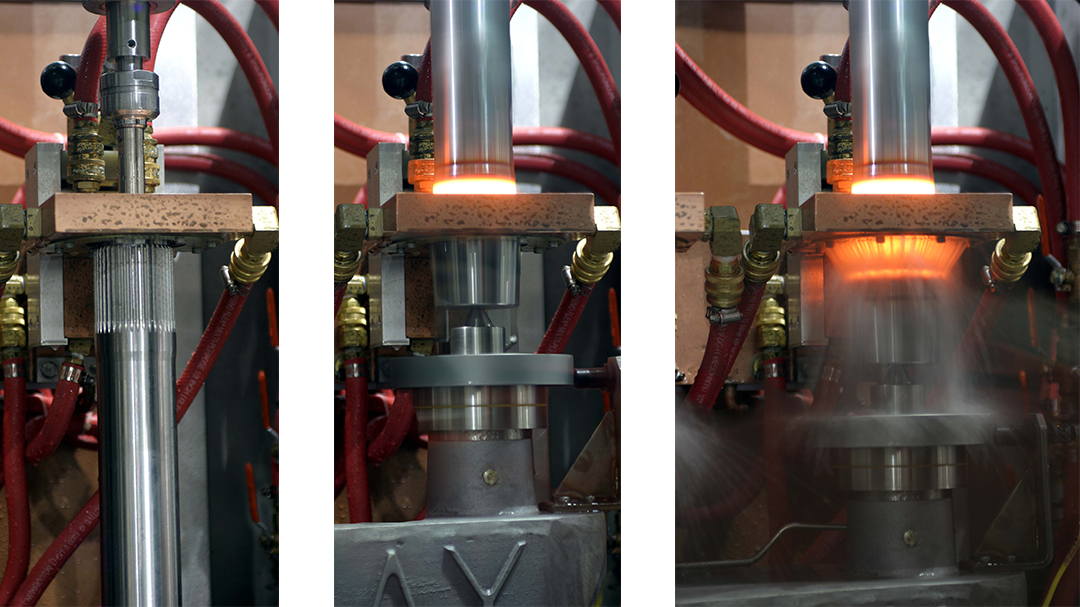

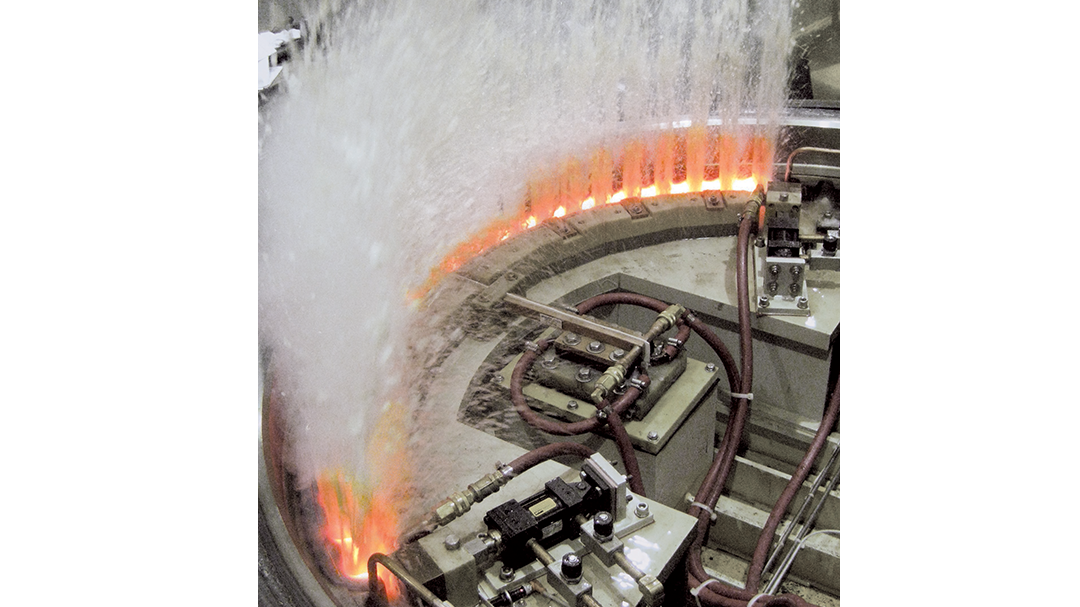

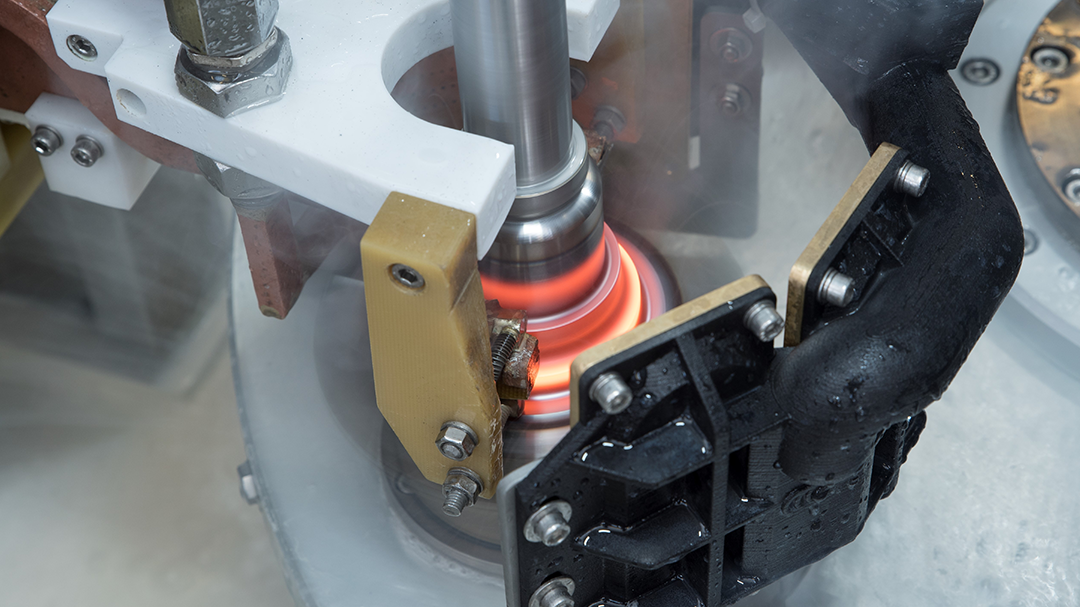

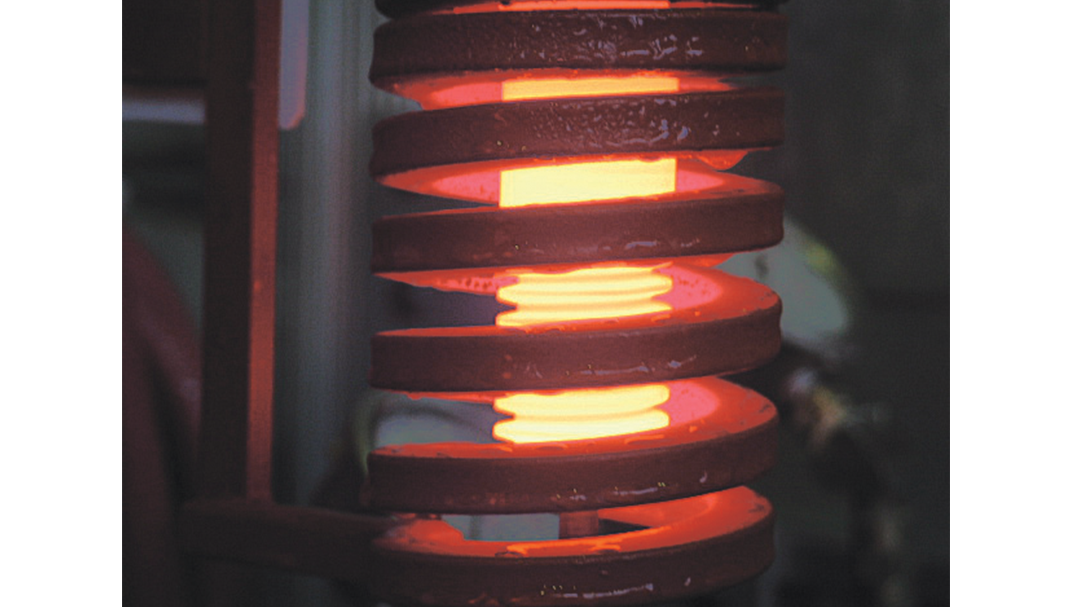

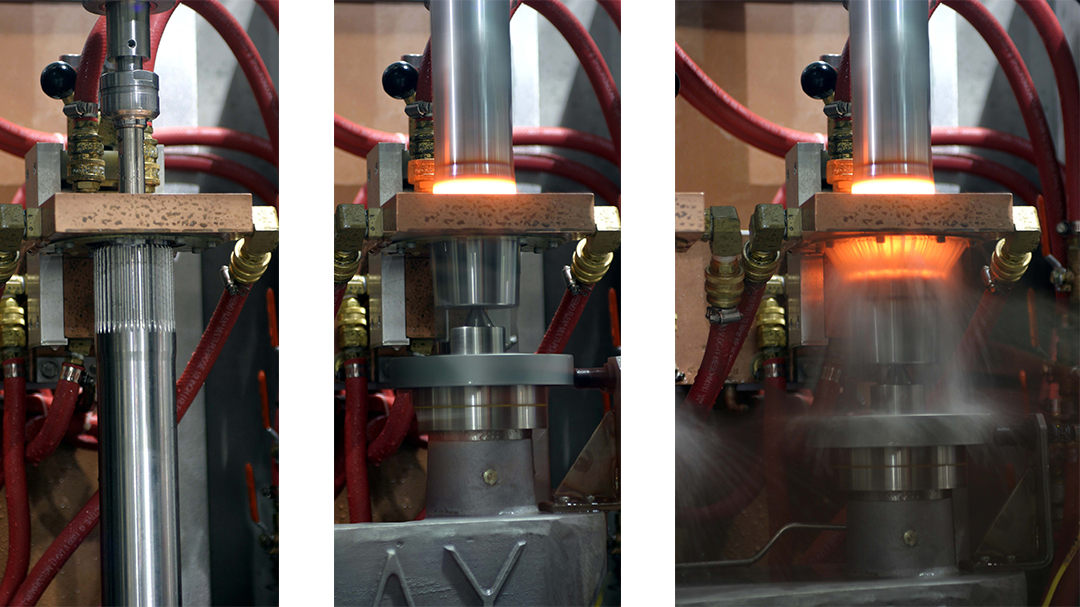

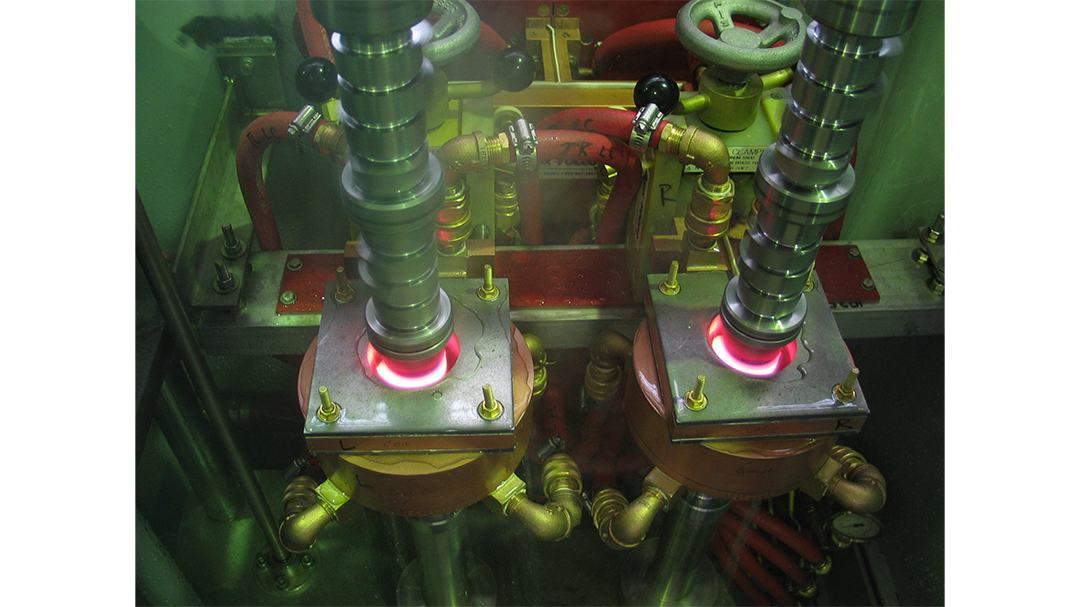

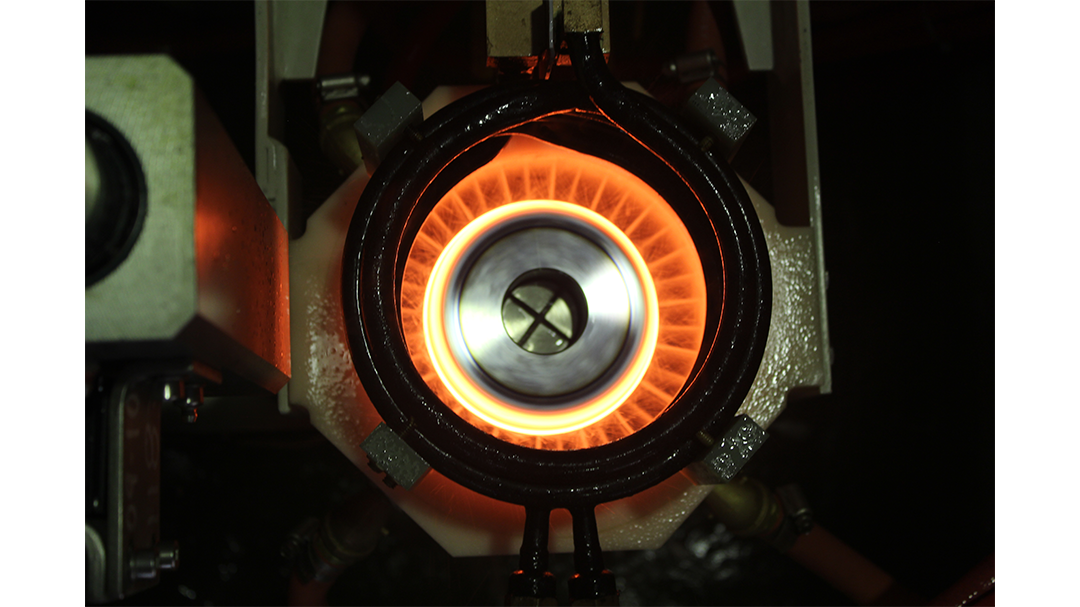

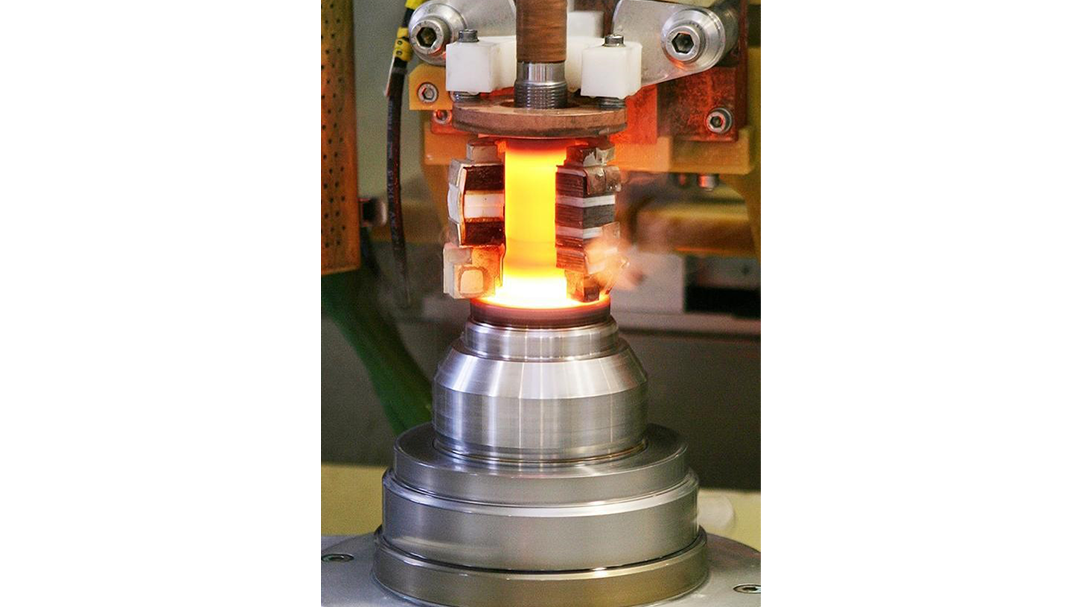

Vertical Scanner

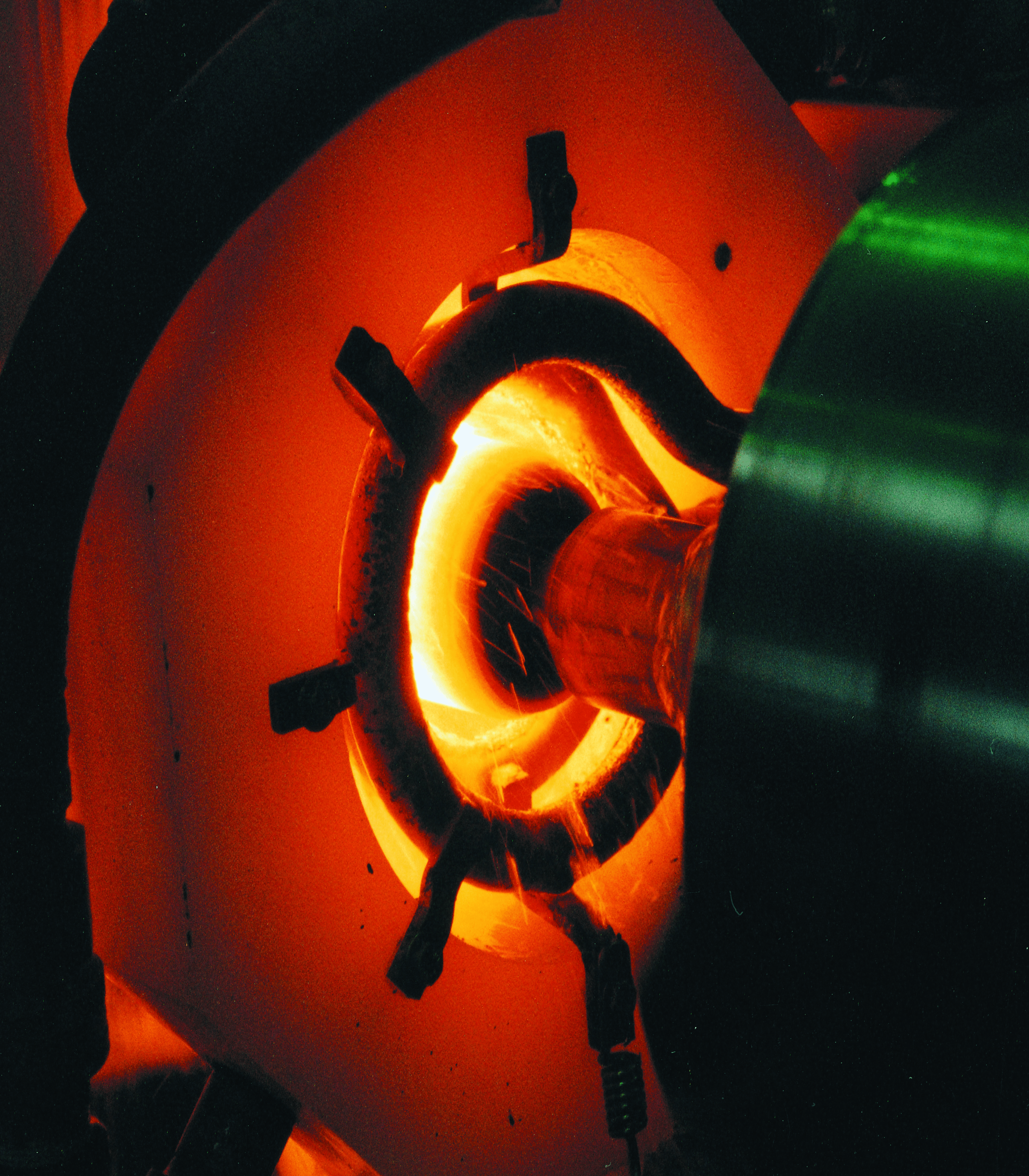

In a vertical induction scanner, the part is either held in a bottom nest or between vertical spindles with continuous heat and quench occurring as it passes through the induction coil. Scanning minimizes the power requirements of the power supply when compared to other heating methods. The part is typically rotated in the scanner for even heat distribution.

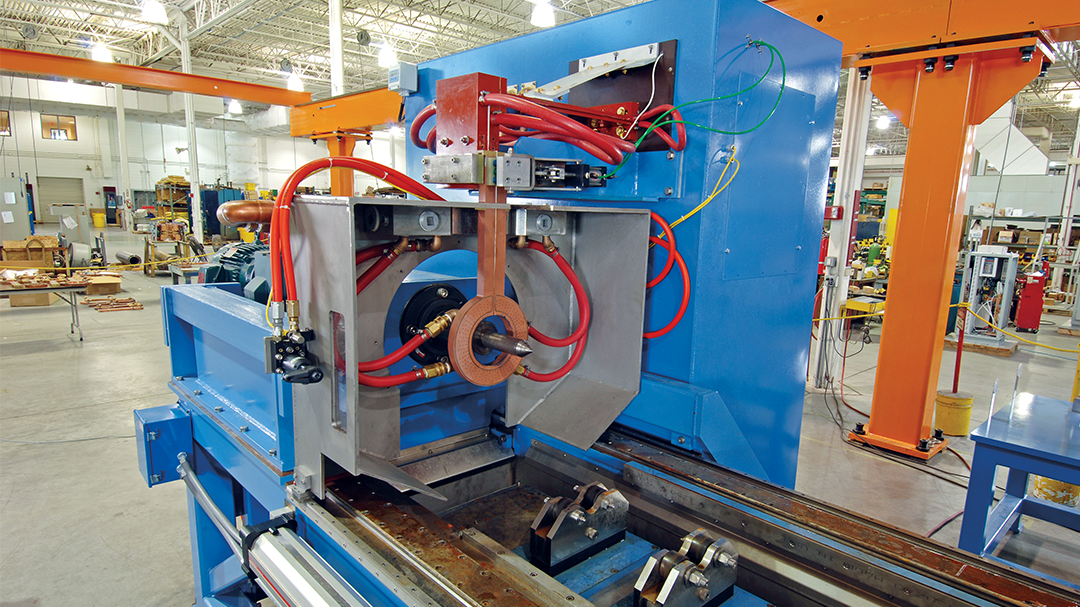

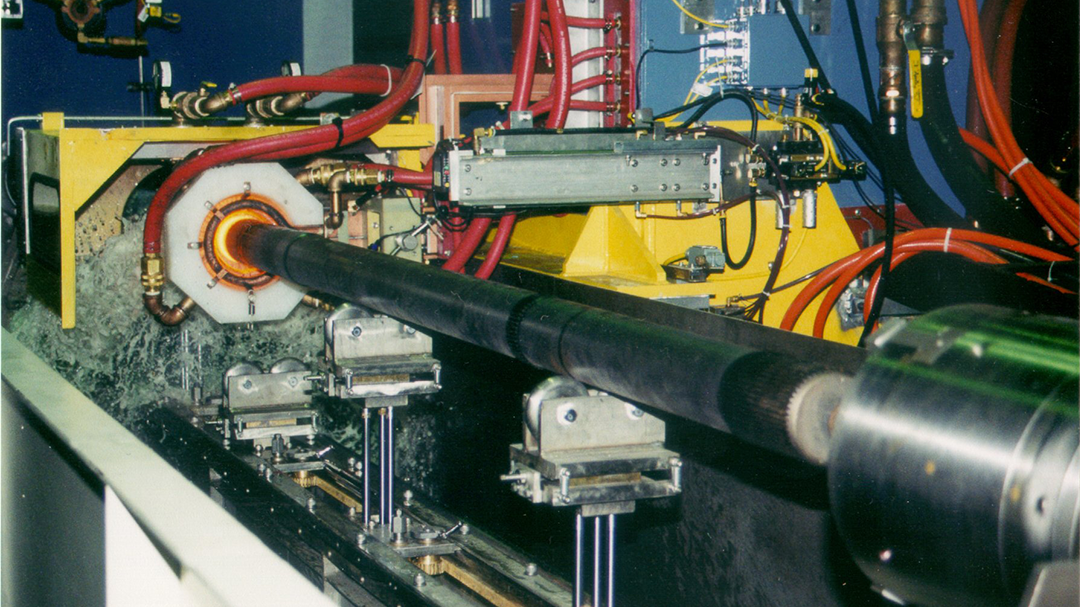

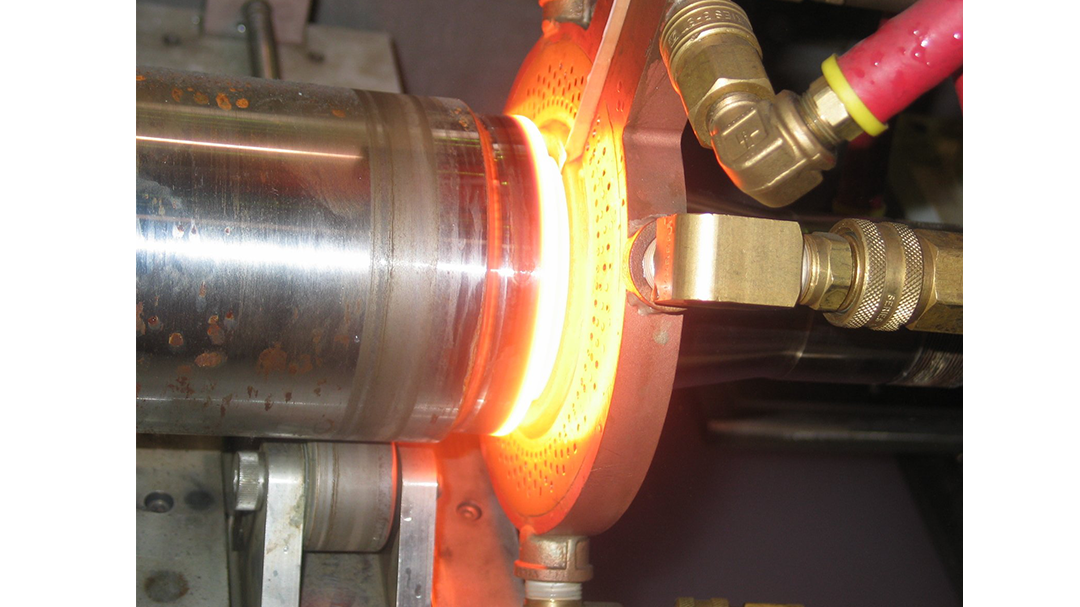

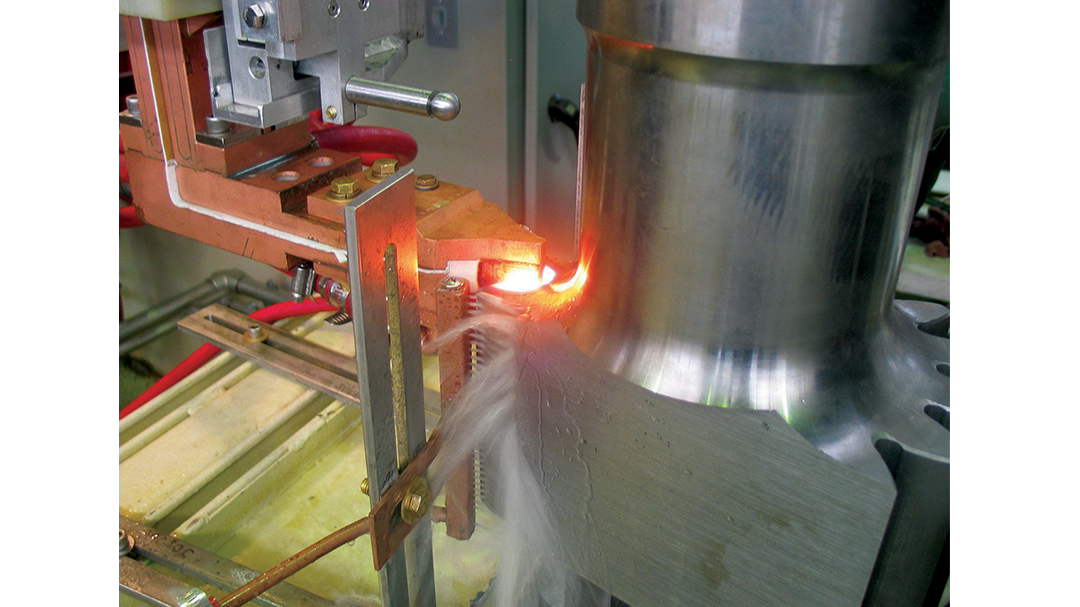

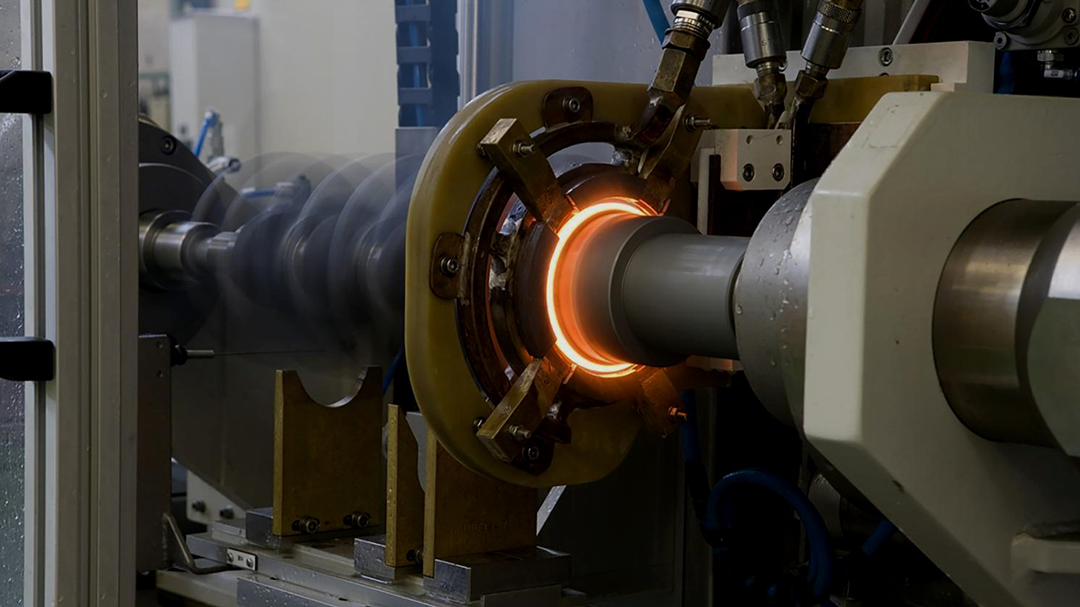

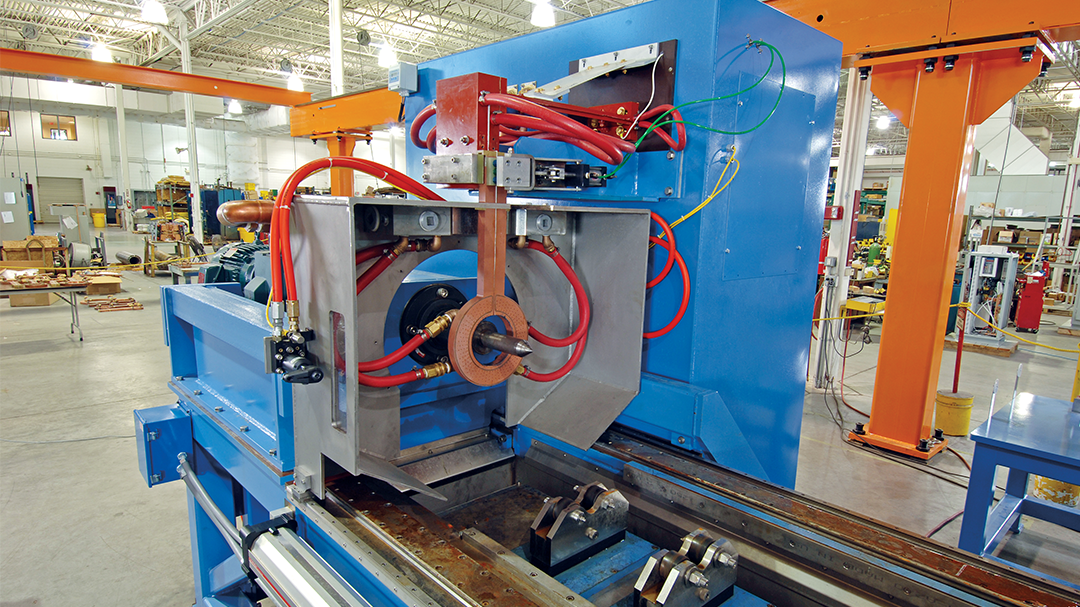

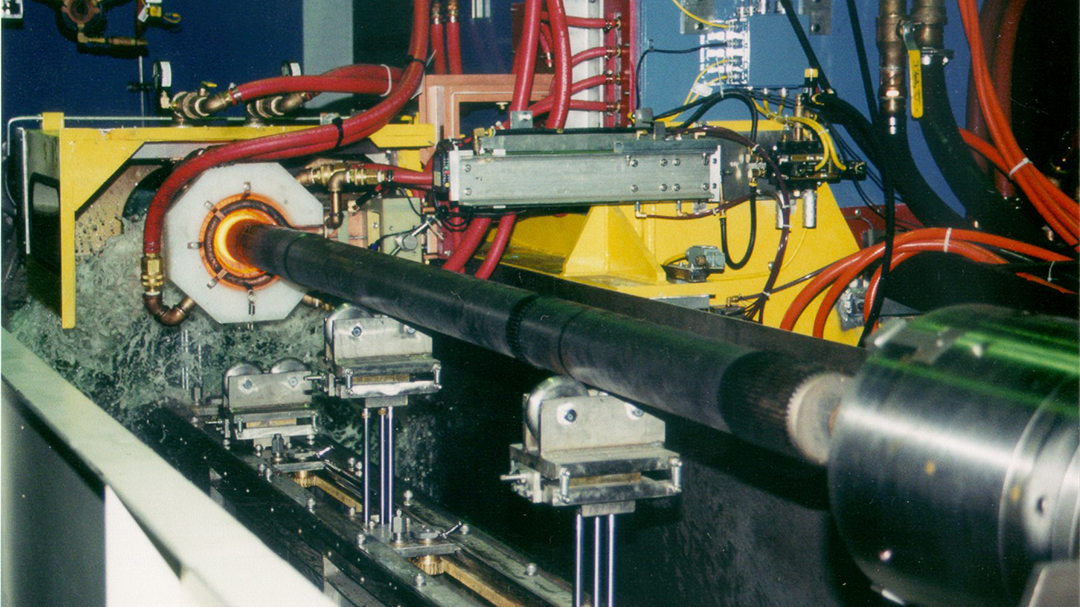

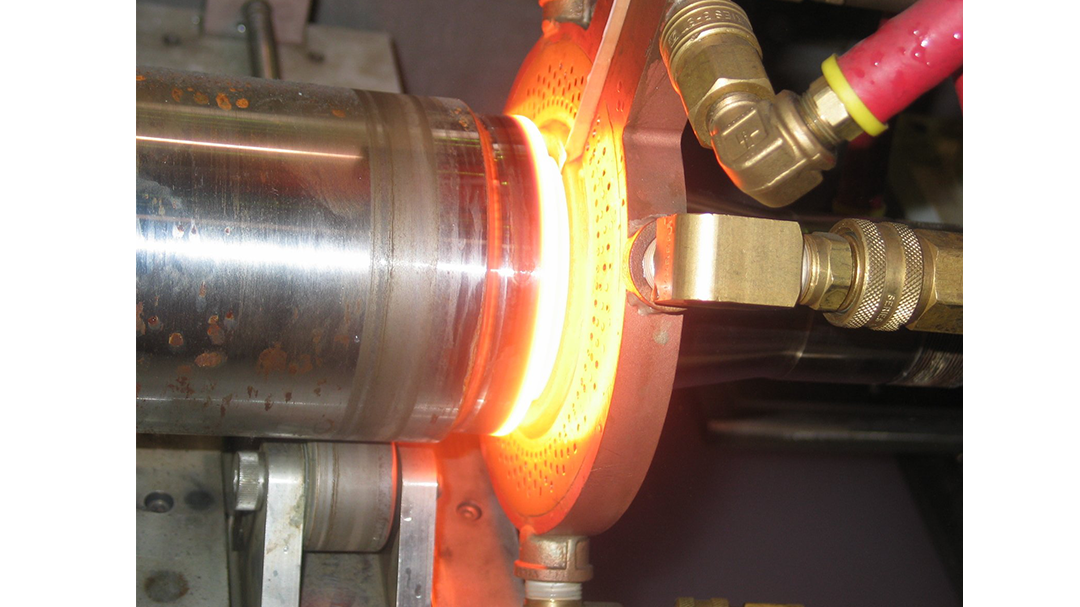

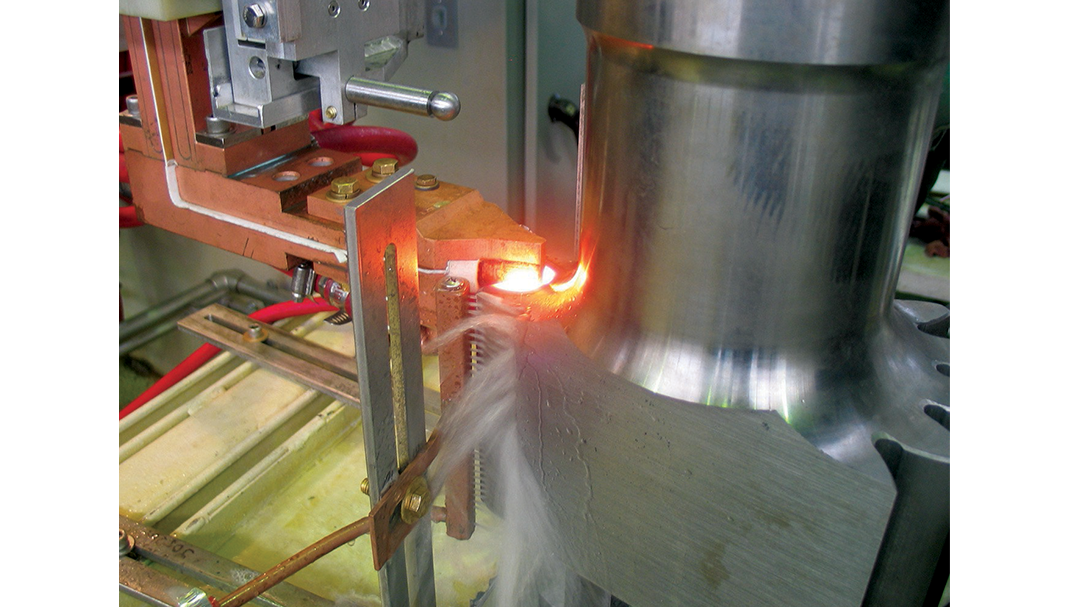

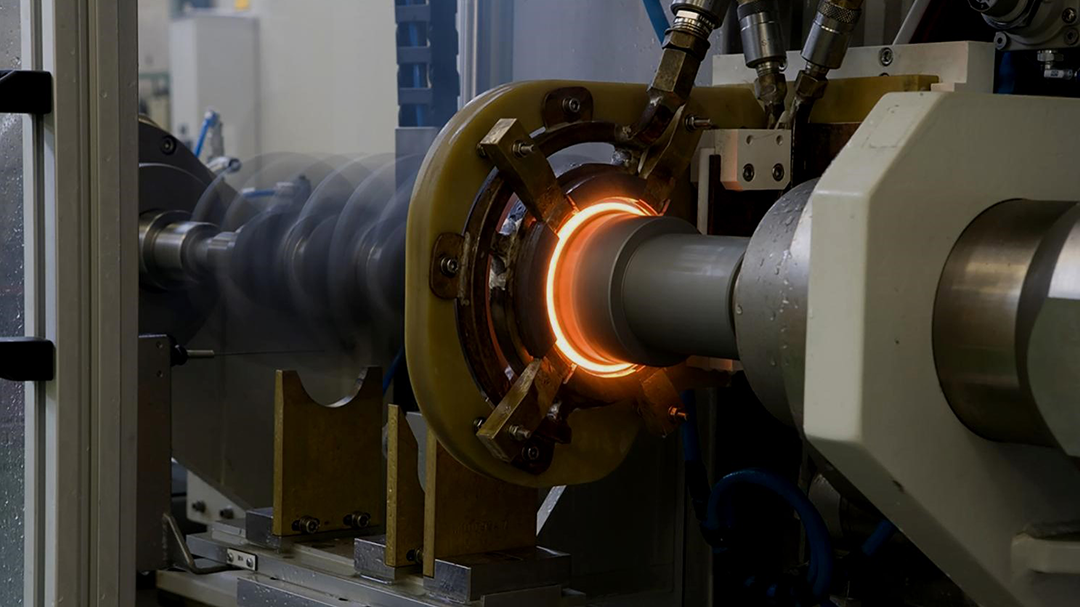

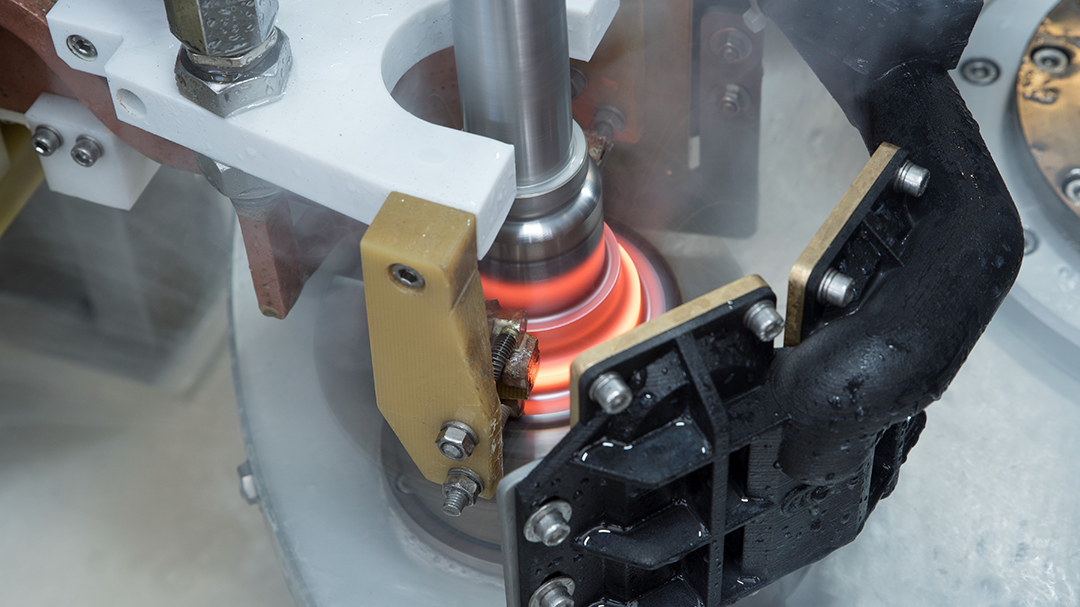

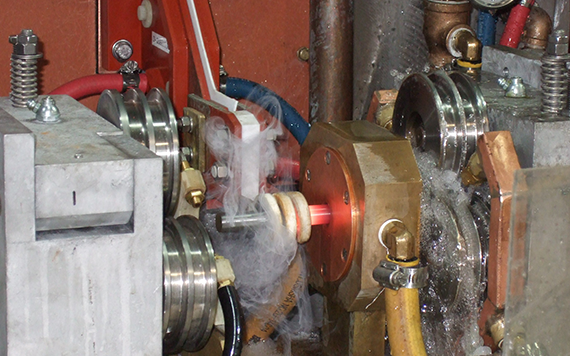

Horizontal Scanner

Horizontal scanners typically heat cylindrical parts from 17" to 132" and up to 19" in diameter. The larger horizontal scanners are used for progressive heating and are fully integrated with induction power, quench systems, rotational drives, servo motions, and system controls. While the part is rotating, the induction coil will travel horizontally along the length of the part while heating and simultaneously quenching the parts.

Here, strut shafts are case-hardened and tempered using a spin feed system. Other applications include linear shafts, ball screws, mill rolls, and axle shafts, ranging on drum roll scanners, lathe-type scanners, and in-line systems.

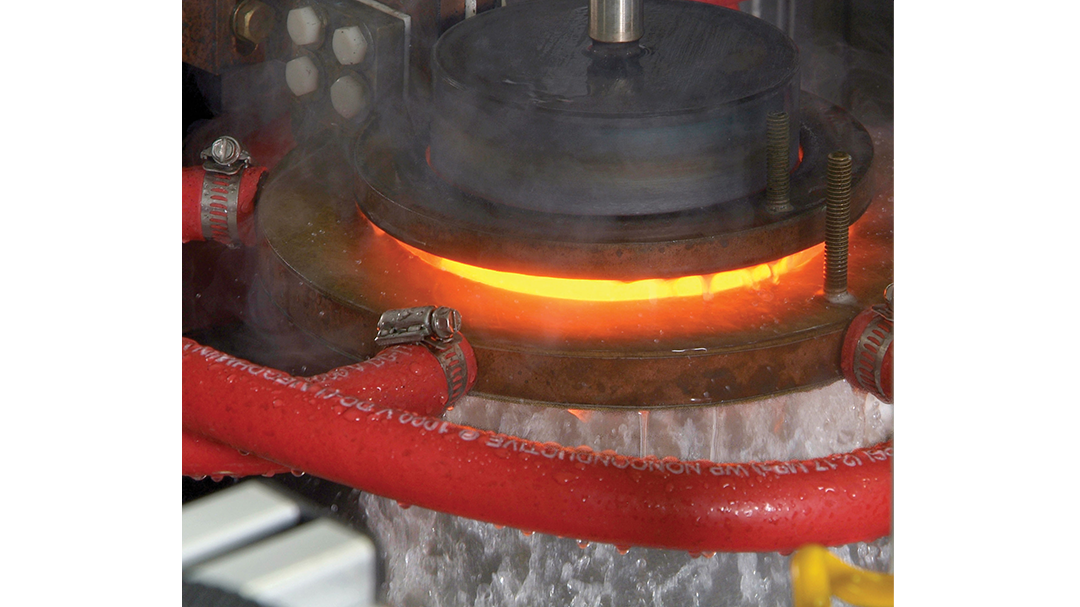

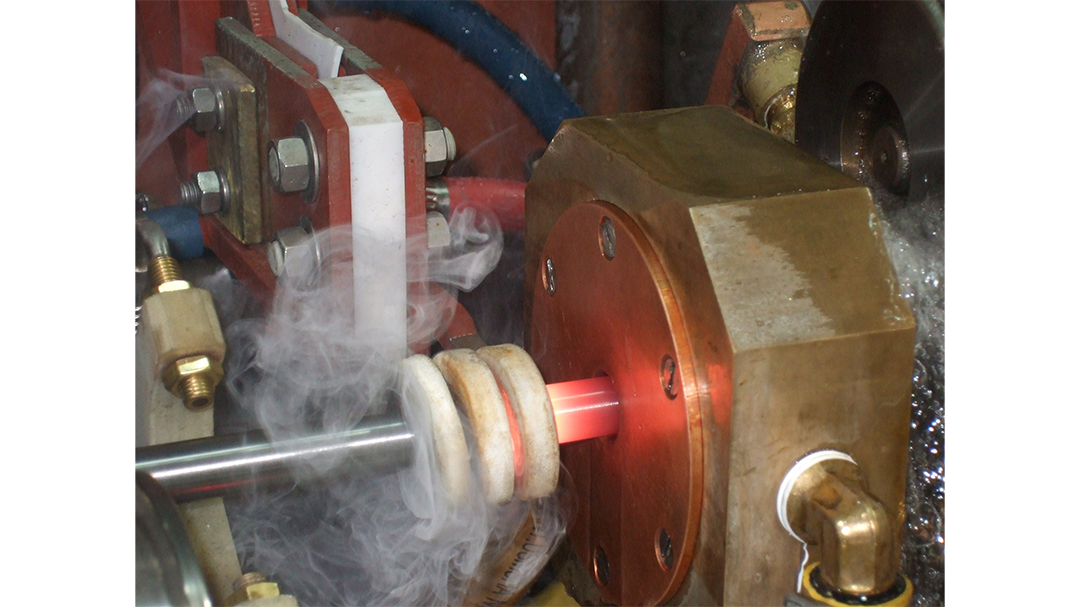

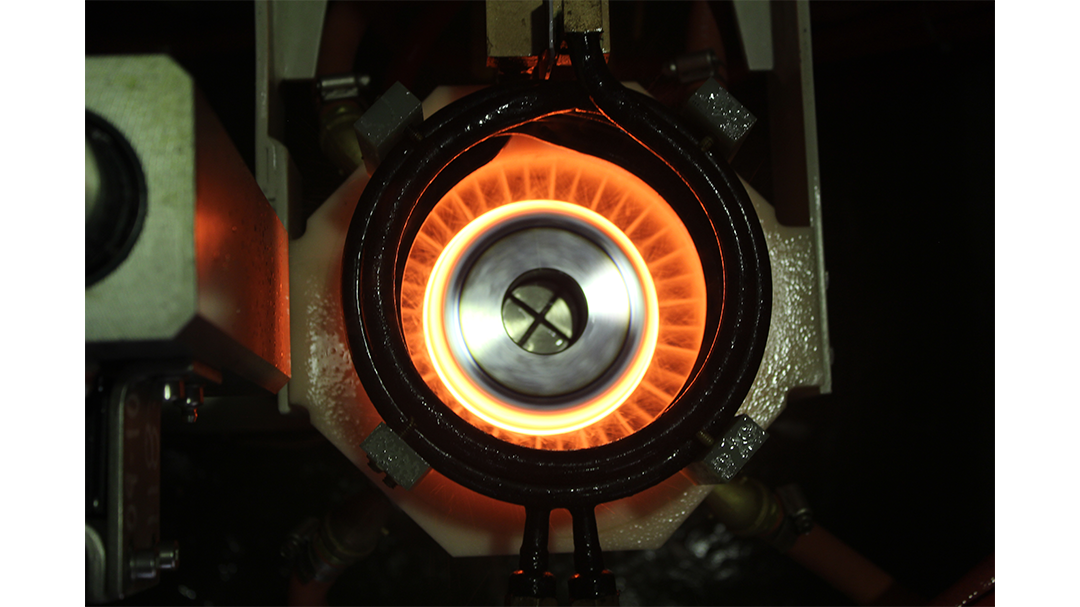

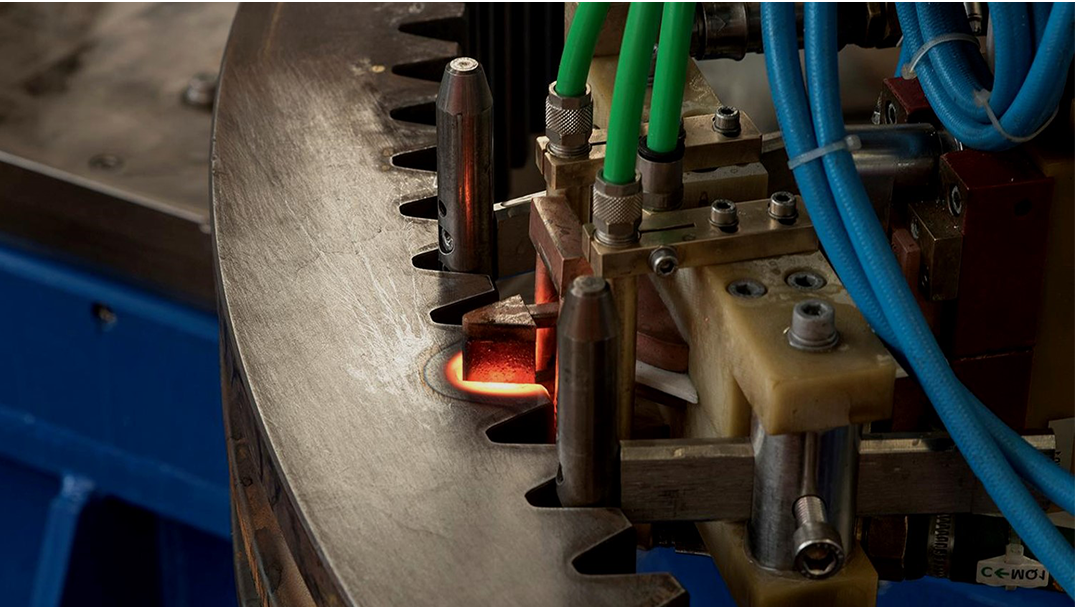

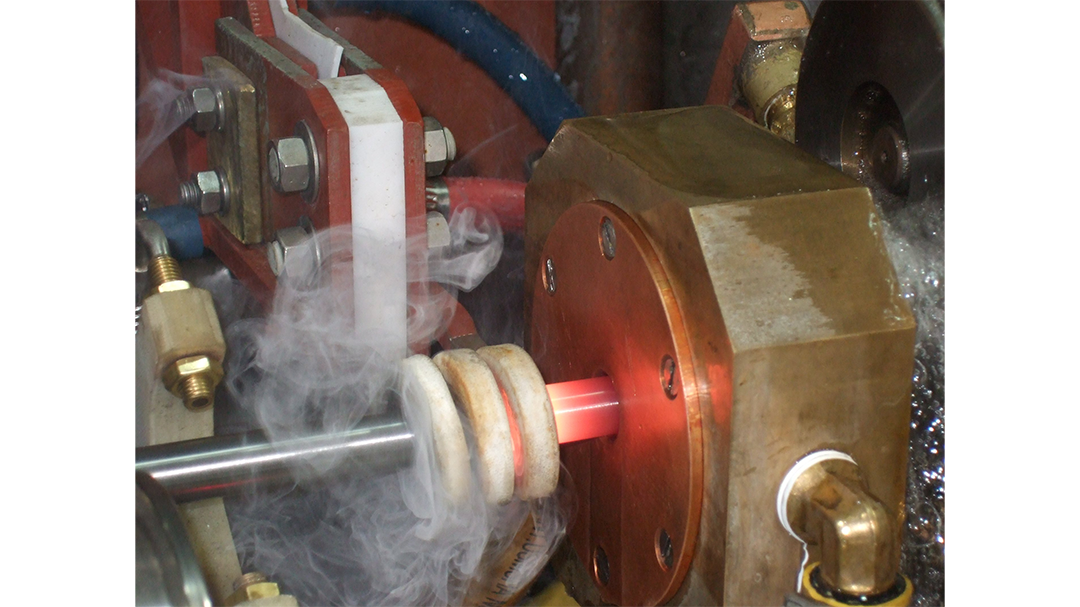

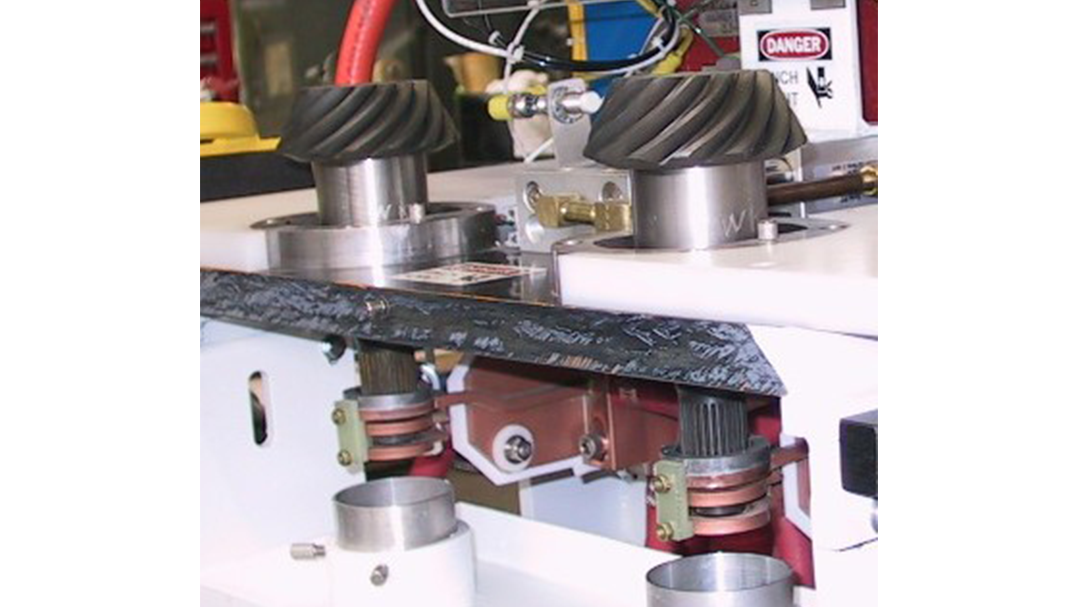

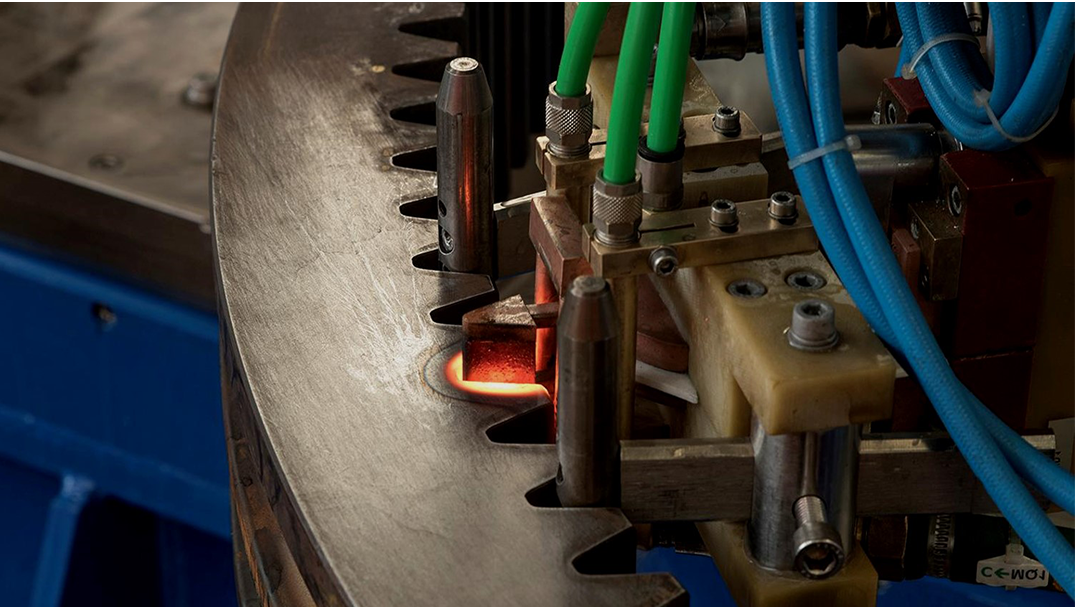

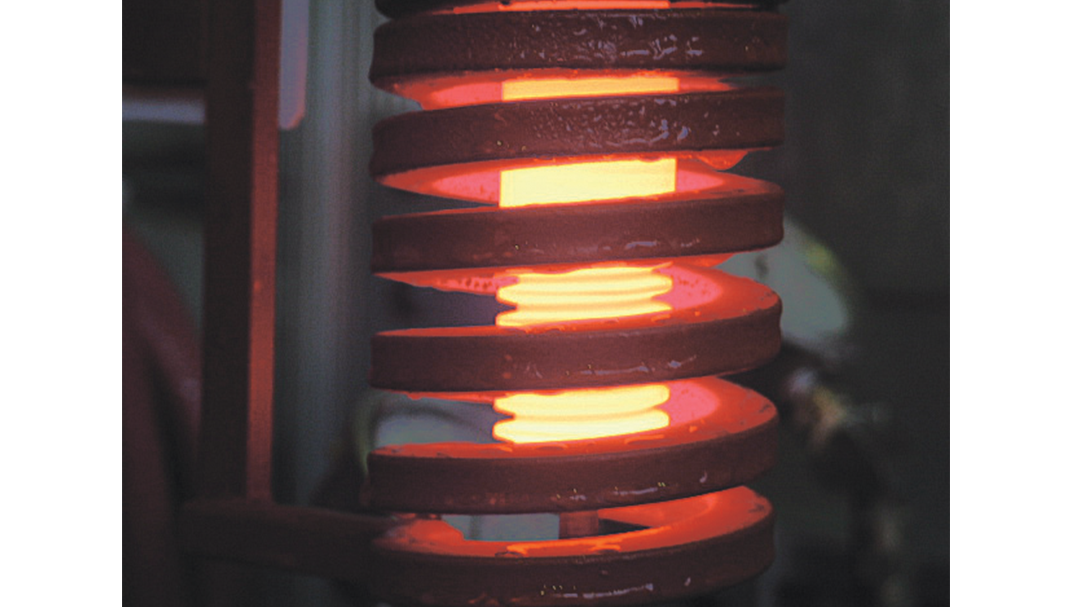

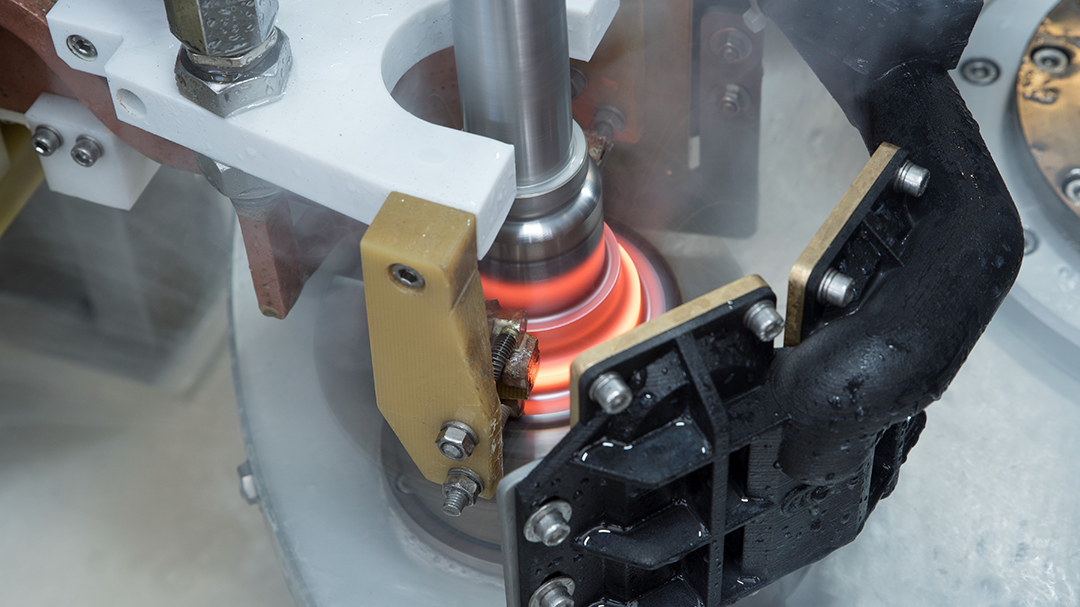

Tooth x Tooth Scanner

Small, medium, and large sprockets and gears are induction hardened using a tooth-by-tooth scanning and quench method. This precise process can be performed on large spur and helical gears up to 180" in diameter and 15,000 lbs. The three-axis positioning controls confirm consistent induction and coil-to-tooth alignment to ensure the proper heating pattern and case depths on every tooth.

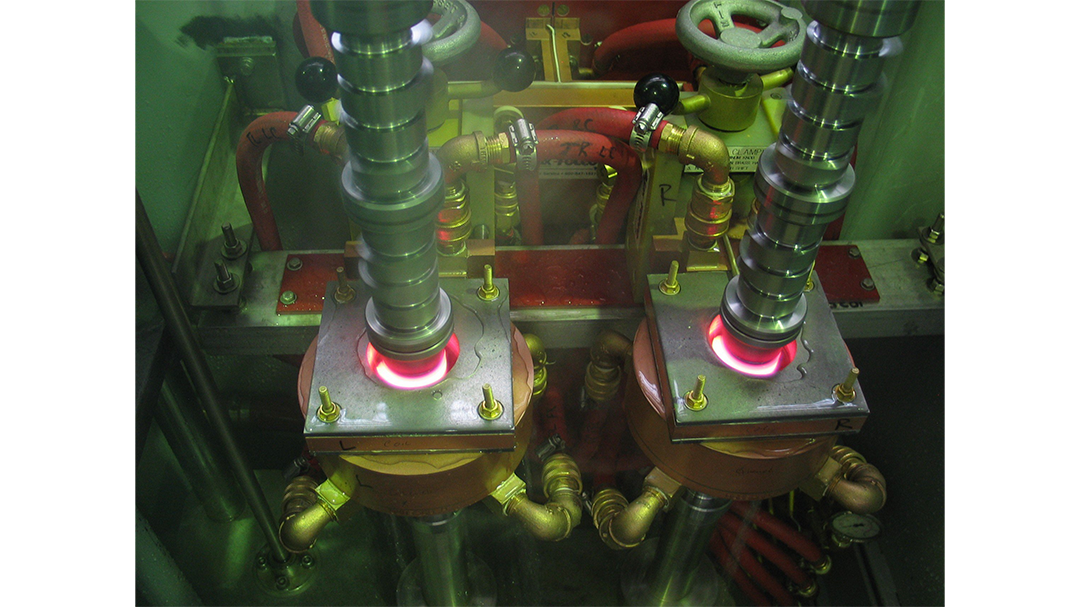

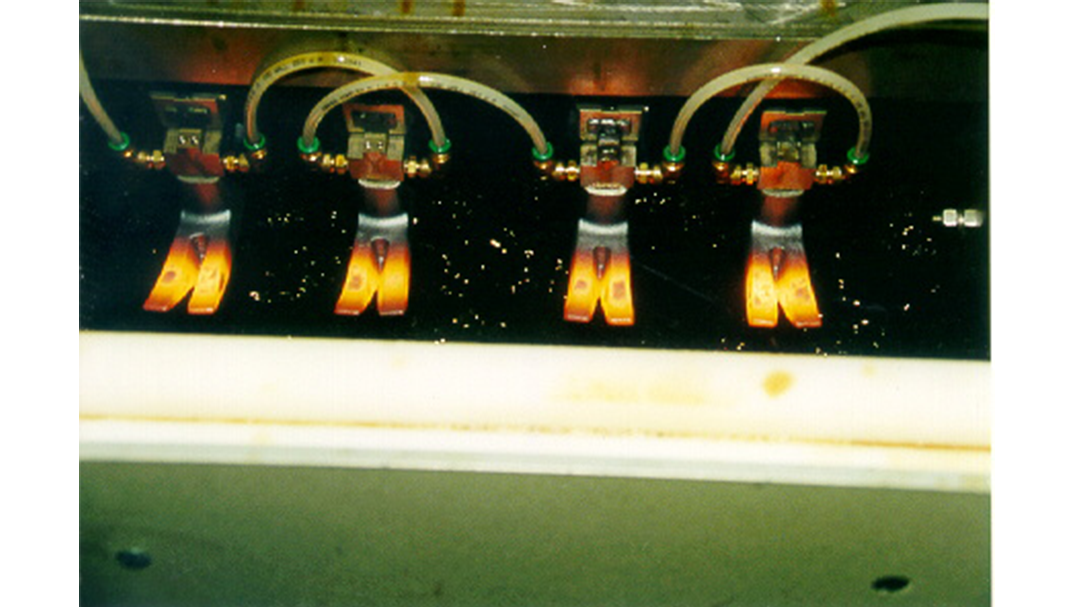

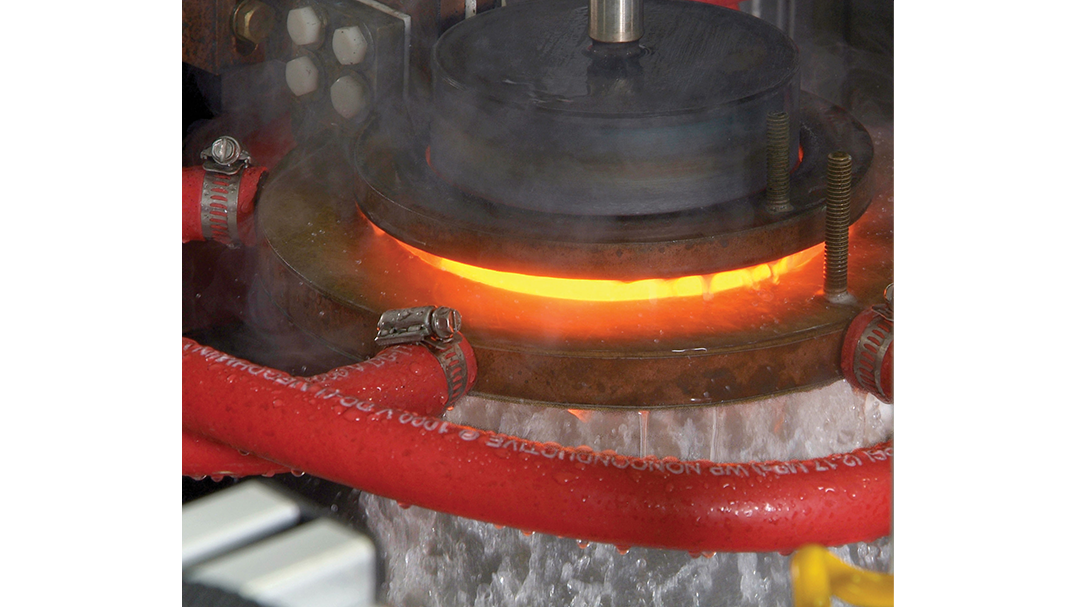

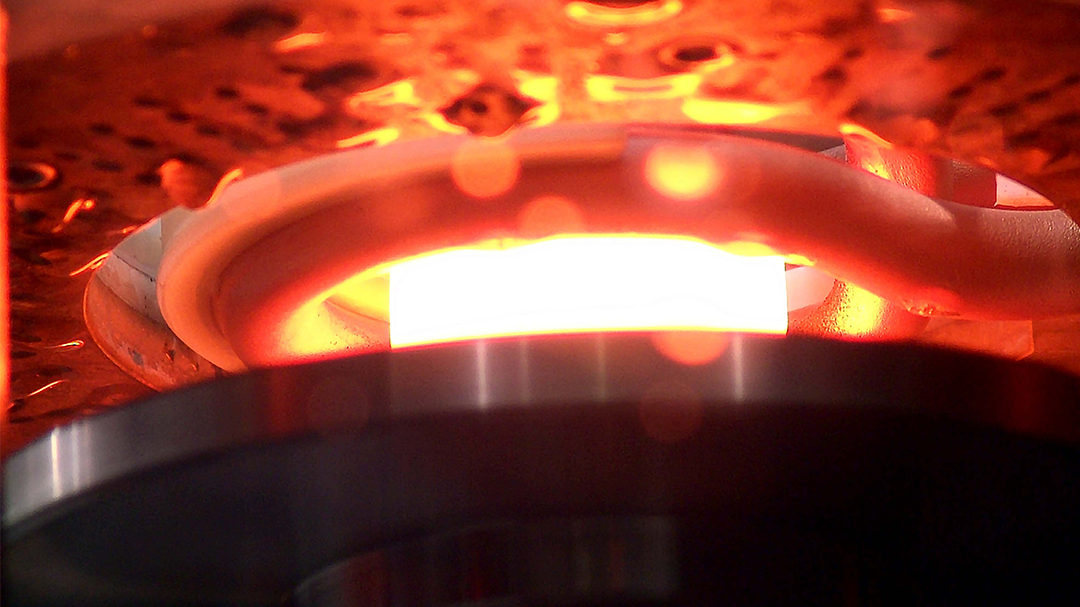

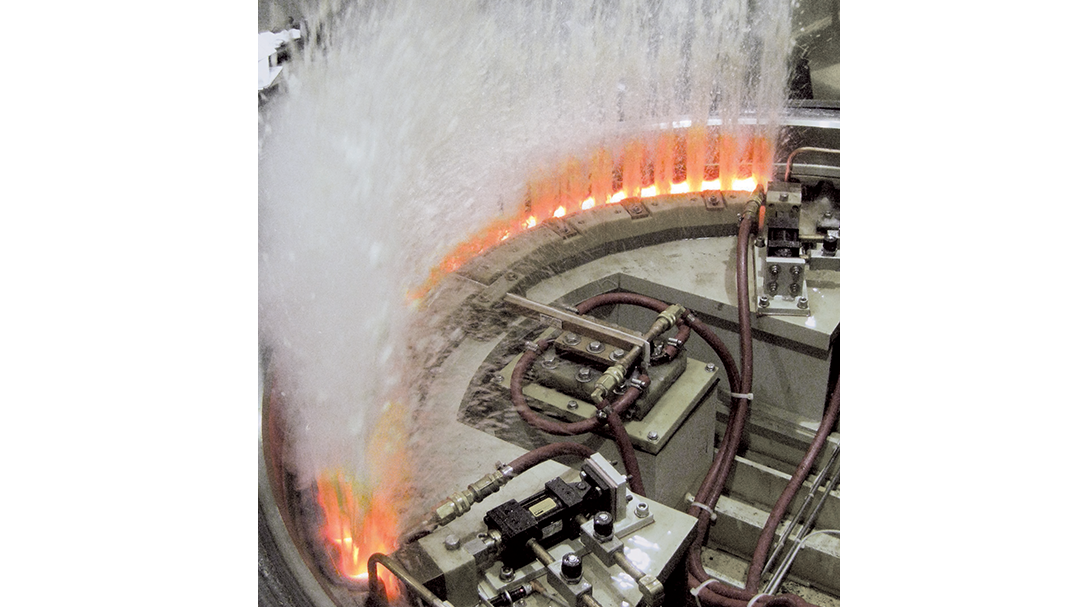

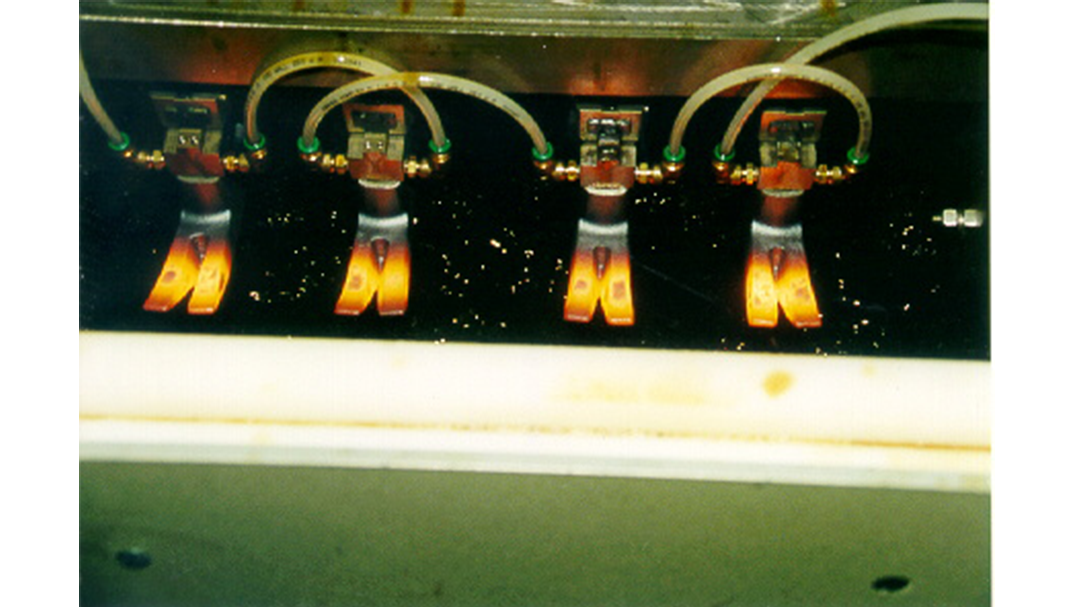

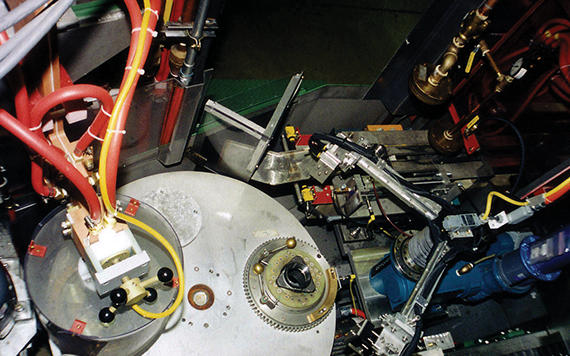

Rotary Indexing Table

A Rotary Indexing or Dial Table enables the processing of multiple parts, providing faster throughput in a compact footprint.

Here, driveline components are processed at a high production rate on a rotary indexing table.

Heat Treating Resources

Sustainable Advantages with Induction

Oct 01, 2024 by Ajax TOCCO MagnethermicAdvancements in technology continue to push the limits of efficiency and reliability, aligning with efforts to make industrial processes more sustainable.

Development Of A State-of-the-Art Crankshaft Hardening System

Aug 03, 2007 by Ajax TOCCO MagnethermicLearn how Ajax TOCCO Magnethermic developed an improved automotive crankshaft hardening system that meets market requirements.

Induction Tooling – Advancements In Induction Heating Tooling Technology

Aug 03, 2007 by Ajax TOCCO MagnethermicThe induction heating tooling industry has made progress, but there still is a long way to go to advance the technology. Learn more.

Equipment & Hardware Materials Technology

Apr 02, 2007 by Ajax TOCCO MagnethermicThe charter of the ASM Heat Treating Society’s R&D Committee is to identify future technological needs of the heat treating industry. Learn more.

Things To Remember About Induction Heat Treating

Apr 02, 2007 by Ajax TOCCO MagnethermicLearn about the factors that make induction heat treating a process of choice for many engineers as well as some basic tips to be mindful of.

Ajax TOCCO Magnethermic Awarded Order for Induction Scanner to Harden Transmission Components

Apr 11, 2013 by Ajax TOCCO MagnethermicAjax TOCCO has been awarded an order for an industrial-duty, dual-spindle servo-controlled vertical scanner to induction harden inner rings used in transmissions. Learn more.

Thank you for requesting access to this brochure.

You can access your download by clicking here.