Heat Treating Solutions

Induction Heat Treating

Heat treating is a process used to alter the metallurgical properties of metal products by heating to specific temperatures to achieve a desired result, such as hardening (case/surface or through), softening, annealing, strengthening, tempering, stress relieving, normalizing, and quenching.

The key requirements to ensure successful results are precise control over temperature, time, and cooling rate.

Advantages of Induction

Induction heating is the most energy-efficient and precise method for applying heat during the heat treating process. This process enables high production rates that meet the most demanding metallurgical requirements.

Localized heating and direct coupling into the part minimize heat losses and part distortion.

Solutions for You

With over 100 years of technical development and experience, Ajax TOCCO Magnethermic provides what customers want by analyzing their needs and recommending a system of maximum value to do the job reliably, faster, and at the lowest cost.

Related Products

Below, you‘ll find products and equipment related to heat treating. Machines vary from vertical and horizontal scanning systems to single shot or static systems, seamless, lift rotate, linear transfer, intensive quenching, quench press, and more.

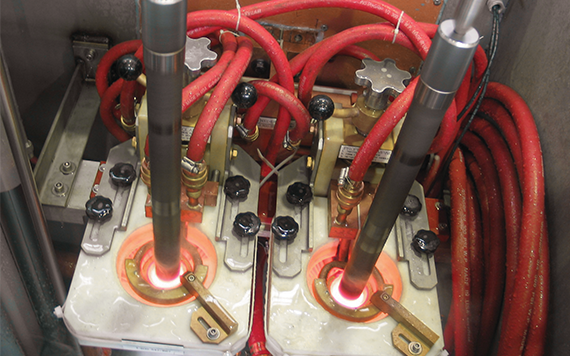

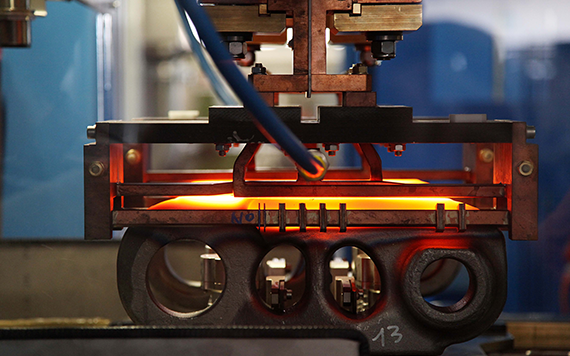

Track Link Hardening

Track links require complex processing to harden the different shapes and dimensions of the part. The frame supports the inductors on a horizontal plane, allowing optimal hardenability of the targeted zones.

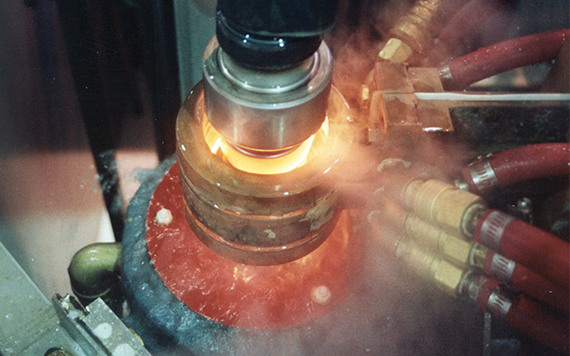

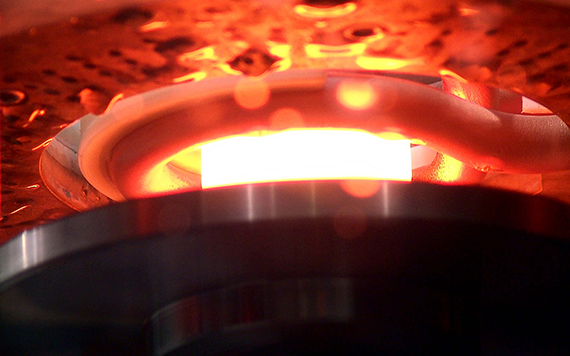

Wheel Hardening

Wheels are heated with induction then quenched to ensure uniformity of processing with minimal part distortion.

.png?width=570&height=356&name=Heat-Treat-Lift-Rotate-Transmission-Outer-Step-Hardening_570x356px%20(1).png)

Gear Hardening

Gears, large and small, can be processed with a tooth-by-tooth induction scanner. Large spur and helical gears can range up to 180 inches and as heavy as 15,000 pounds. The 3-axis controls precisely control inductor and part movement to assure consistent case depths on each tooth.

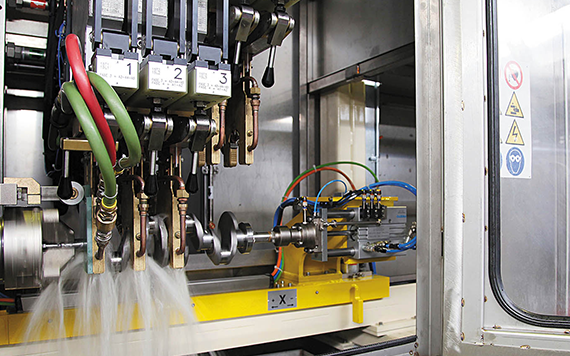

Crankshaft Hardening

Truck engine crankshaft main journals and pins are induction hardened on a three-station cell. Station one hardens the mains while stations two and three harden the pins. The system has five power supplies shared between the three stations, which are robotically loaded and unloaded.

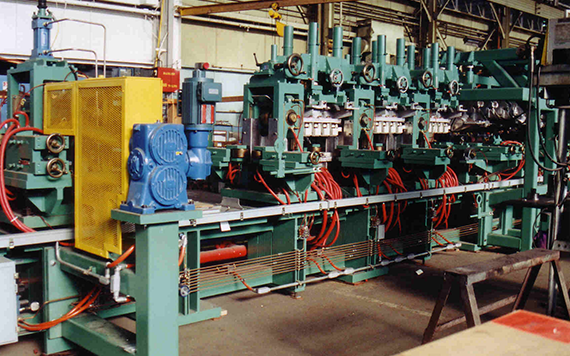

Rail Hardening

Rail hardening with induction can eliminate the need for roller straightening after processing. Capable of head hardening or fully hardening rails, this online hardening process starts with a preheat section to fully austenitize the rail. The post-heat induction transverse flux coils for the rail head and flange soak the rail thermally, providing straightness control, prior to the air quench chambers.

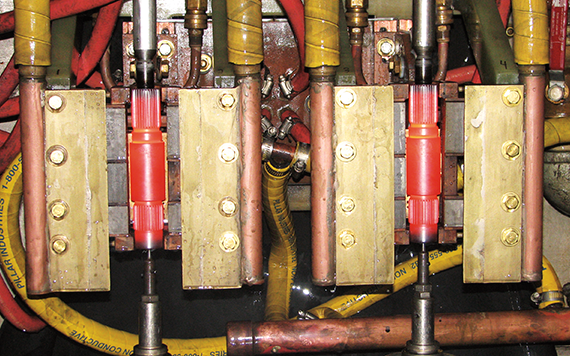

Quench Press

Processing work pieces up to 30 inches in diameter and 11 inches tall, our stand-alone quench press system can be integrated with any up-stream heat source. Quench pressing reduces distortion by controlling the part during the quenching process.

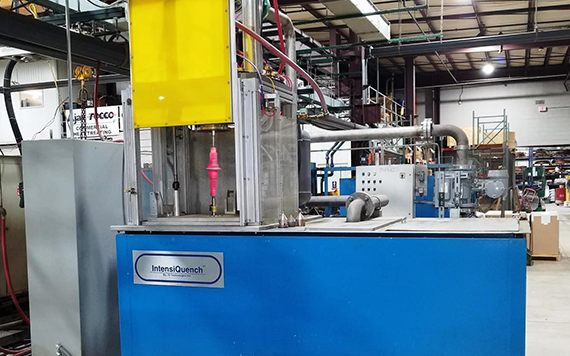

Intensive Quench

Intensive quench is an environmentally safe alternative to carburizing, providing superior mechanical and metallurgical properties in the processing of low alloy steels. This process is ideally suited for in-line manufacturing of parts.

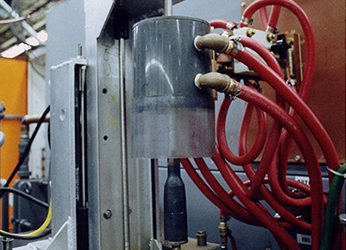

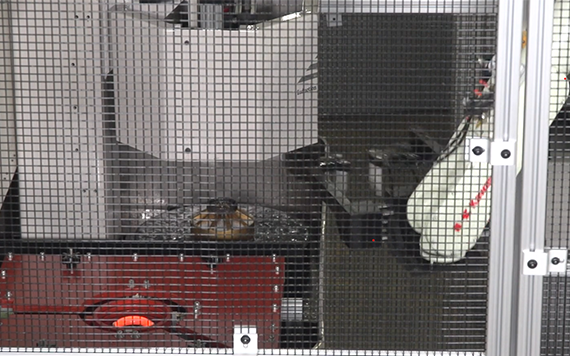

Single Shot Processing

In single shot processing, the part being treated remains stationary in the induction coil during heating and quenching. This alternative method to scanning can provide faster processing times and less part distortion.

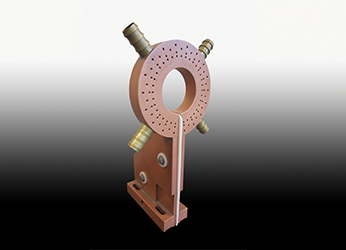

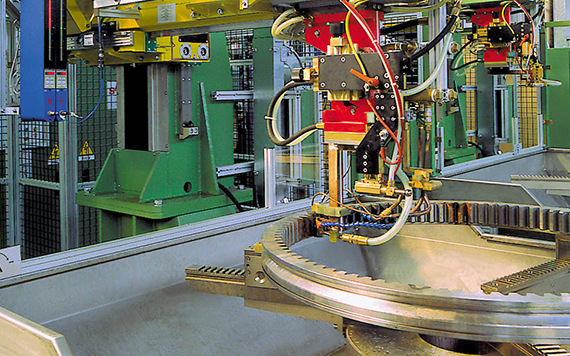

Horizontal Ring Scanning

Precise hardening of rings and gears is maintained through precise control of the induction coil, both mechanically and electrically. Rings can be processed on a single or dual table and can be as large as 9 meters in diameter and 30 tons in weight.

Outer Race Stem Hardening

Inside diameter surfaces of transmission outer races are hardened and tempered on lift & rotate fixtures. A shuttle transfer indexes parts through the spindles.

.png?width=570&height=356&name=Heat-Treat-Lift-Rotate-Transmission-Outer-Step-Hardening_570x356px%20(2).png)